Author:

Reported by Cliff Keys, Editorial Director, Editor-in-Chief, Power Systems Design

Date

11/26/2010

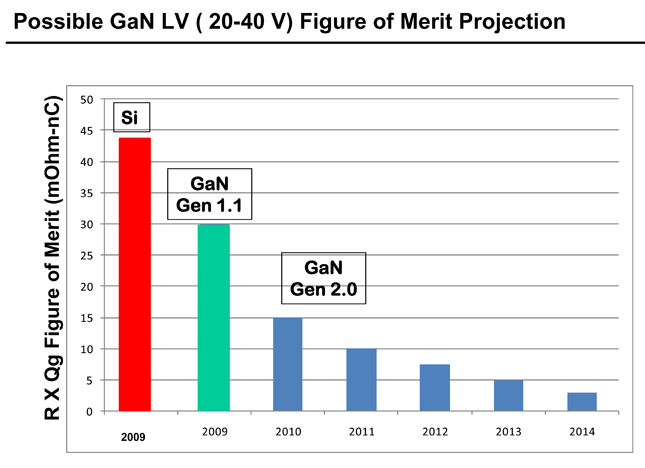

IR demonstrated its GaN technology during the electronica at a press event in Munich. When I say demonstrated, I mean real powered demos showing how these devices can out-perform the �normal' Silicon devices we are more used to. With the drive for energy efficiency together with the need to shrink the power footprint, these devices look set to become a viable differentiator.

With conventional Silicon now reaching maturity, IR's GaNpowIR is a commercially viable GaN-based power device platform based on proprietary GaN-on-Si Hetero-epitaxy utilizing low-cost, high-quality 150mm Si wafer substrates.

The manufacturing process for these devices is CMOS compatible meaning that industry standard, high volume manufacturing disciplines and quality systems can be applied. Extensive intrinsic reliability studies have now been performed and standard product reliability tests applied to IR's device qualification with first production products released back in February 2010. GaN based Power devices represent an excellent choice for dramatically improved power device performance. IR's GaNpowIR platform is now commercially viable and results in high performance, proven stable operation of devices and circuits The first commercialized GaN-on-Si switching power transistor based product, iP2010 is now released. First commercial 600V product is planned for release in CY 2011. IR's GaNpowIR platform has overcome the greatest cost barriers of GaN based power devices and is poised to address a wide range of power conversion applications from 20-1200V. The company's family of 25V and 30V Performance PQFN Power MOSFETs Deliver High Density Solution for Industrial Point-Of-Load. Family of 25V and 30v Devices Featuring IR's Latest HEXFET® MOSFET Silicon in a Performance 3 x 3 PQFN International Rectifier, announced the introduction of a family of 25V and 30V devices featuring IR's latest HEXFET® MOSFET silicon in a new performance PQFN 3 x 3 package that delivers a high density, reliable and efficient solution for DC-DC converters in telecom, netcom, and high-end desktop and notebook computer applications.

As a result of improved manufacturing technology, IR's new performance PQFN 3 x 3 package enables up to 60 percent higher load current capability than standard PQFN 3 x 3 devices in the new compact footprint while overall package resistance is significantly reduced to deliver extremely low on-state resistance (RDS(on)). In addition to the low RDS(on), the new performance PQFN package offers enhanced thermal conductivity as well as improved reliability and is qualified to industrial standard and moisture sensitivity level 1 (MSL1). The performance PQFN package technology is also applied to 5 x 6 mm footprint devices enabling designs requiring more current without the need for additional footprint compared to standard PQFN 5 x 6 devices. The family includes devices optimized for use as control MOSFETs featuring low gate resistance (Rg) to reduce switching losses. For synchronous MOSFET use, devices are available as a FETKY® (monolithic FET and Schottky diode) configuration to offer enhanced efficiency and EMI performance by reducing reverse recovery time. "The new family of performance PQFN package devices offers a high density, highly reliable and flexible solution optimized for DC-DC applications. Moreover, by expanding IR's PQFN offering, customers can now select from many package combinations to achieve the optimal result for their design," said George Feng, marketing engineer for IR's Power Management Devices Business Unit. With a low profile of less than 1mm, the devices are compatible with existing Surface Mount Techniques, feature industry-standard footprint and are RoHS compliant. High Power, High Speed, High Density Discrete Solutions for Energy-Efficient DC-DC Automotive Applications International Rectifier introduced the AUIRS2191S 600V driver IC and AUIRGP50B60PD1 600V non-punch-through (NPT) insulated gate bipolar transistor (IGBT) for use in energy-efficient DC-DC automotive applications. The new devices feature fast switching speed and high power density making them well suited for use in high frequency DC-DC applications including high power DC-DC SMPS converters used in electric and hybrid electric vehicles.

The AUIRS2191S dual channel 600V driver IC enables independent control of the high- and low-side in a half-bridge topology. The device provides up to +3.5A/-3.5A (source/sink) current capability with very fast propagation delay times of 90ns (typical) making the switches highly responsive to driver command. The IC also features independent control of the high- and low-side to allow customization of dead time to minimize power loss and matched propagation delay on both channels. Operating junction temperature (Tj) up to 150°C and under-voltage lockout for both channels are also offered, in addition to Vss logic ground offset pin separated from COM power ground pin to provide higher immunity to transient shifts on COM voltage. The AUIRS2191S IC features proprietary high-voltage integrated circuit (HVIC) and latch immune CMOS technologies to offer ruggedized monolithic construction. The output drivers offer a high pulse current buffer stage designed for minimum driver cross-conduction. The floating channel can be used to drive an N-channel power MOSFET or IGBT in the high-side configuration, operating up to 600V. In addition, the devices feature benchmark negative voltage spike immunity for reliable operation even under extreme switching conditions and short circuit events. The AUIRGP50B60PD1 600V non-punch-through (NPT) insulated gate bipolar transistor (IGBT) is co-packaged (Co-Pack) with a 25A ultra fast soft-recovery diode capable of operating at switching speeds up to 150kHz, making it an ideal substitute for MOSFETs in high power SMPS applications. The new automotive-qualified IGBT utilizes IR's thin wafer technology, which ensures shorter minority carrier depletion time and hence faster turn-off. The device's negligible turn-off tail current and low turn-off switching loss, or EOFF, enables designers to achieve higher operating frequencies. The improvements in switching performance, combined with optimized (positive) thermal coefficient characteristics and the lower gate turn-on charge, enable higher current density. Positive temperature coefficient ensures safe, reliable, high efficiency current sharing when operated in parallel. "As part of IR's ongoing commitment to provide leading-edge automotive dedicated solutions, these new devices efficiently deliver the very fast speed and high voltage requirements demanded by automotive DC-DC applications," said Marzak Li, product marketing manager, IR's Automotive Products Business Unit. The devices are qualified according to AEC-Q10x standards, feature an environmentally friendly, lead-free and RoHS compliant bill of materials, and are part of IR's Automotive focused Zero Defect Initiative. Datasheets and qualification standards are available on the International Rectifier website at www.irf.com.