Author:

David Morrison, Editor, How2Power

Date

11/09/2012

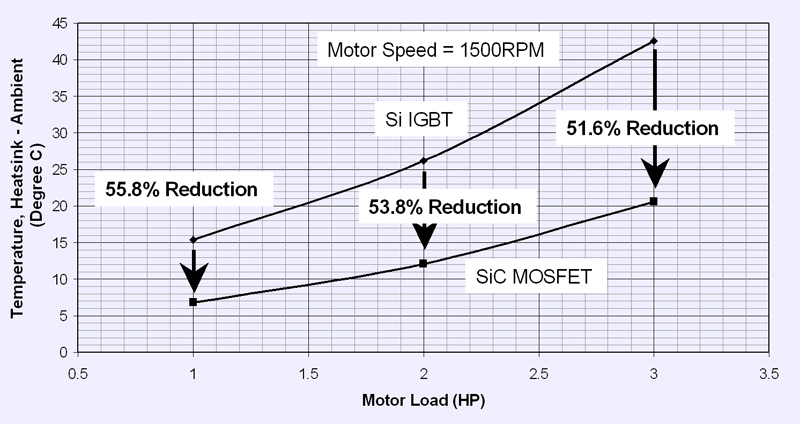

Silicon-carbide technology has the potential to enhance performance in numerous high-power applications. However, many power electronics engineers may have questions about the readiness of SiC power devices for their current design projects and the impact these devices may have on their designs. In a recent article in How2Power Today, Paul Kierstead of Cree assesses the readiness and potential impact SiC MOSFETs and Schottky diodes on motor-drive applications. In Silicon Carbide Power Solutions Are Ready To Revolutionize Motor Drives, Kierstead analyzes the impact of his company's high-performance transistors and diodes on a standard variable-frequency motor drive. The author breaks down the application into its three major power conversion functions: • the dc-ac power inverter responsible for driving the motor • the ac-dc rectifier section with built-in regen function and • the auxiliary power supply that powers digital control and other functions. Focusing on each of these sections, Kierstead explains how replacing silicon IGBTs and fast-recovery PiN diodes with SiC MOSFETs and Schottkys achieves benefits such as higher efficiency, simplified topologies, reduced parts counts, smaller components, and higher-frequency operation. In particular, data is presented to support the claims of improved efficiency enabled by the SiC devices (see figure).

The author notes that the discussion mainly concerns motor drives operating from mains voltages up to 690 V AC with a 20% high-line value plus design margin. The silicon devices that have been developed for these applications, he says, are pushing the envelope of silicon performance. In contrast, the 1200-V and 1700-V SiC devices now available are barely scratching the surface of SiC's potential. Kierstead observes that SiC devices with 10-kV blocking voltages may be commonplace one day. The author addresses the reliability issue by pointing to successes achieved with SiC Schottkys (350 billion hours in field operation with his company's devices), noting their superior failure rate versus silicon diodes. Kierstead predicts that SiC MOSFETs will in time prove to be similarly robust. This article also touches on the factors that have historically limited SiC's usage in the motor-drive market. These include cost, the lack of device availability with suitable current and voltage ratings, and the lack of power module packaging. The designers' unfamiliarity with the technology has been another factor. However, as Kierstead explains, today there is a wider array of SiC products (Schottkys, MOSFETs, and JFETs) with device ratings for diodes ranging from 1 to 50 A at blocking voltages from 600 to 1700 V. In addition, SiC power modules in standard and custom configurations are now in development. To read the full story, see the August 2012 issue of How2Power Today, online at www.how2power.com/newsletters.