Author:

Dr. Jae Inh Song, Executive VP, Sales/Marketing, Dongbu HiTe,k Korea

Date

09/06/2011

Automotive electronics has emerged as one of the most important applications for integrated circuits. The expanded use of automotive electronics and concomitant semiconductor content per vehicle shows no signs of slowing down According to one recent forecast, the average semiconductor content per automobile is expected to jump to $350 this year, representing a 15% increase over last year. This content-per-vehicle momentum is expected to reach $425 by 2014, posting an average of 9% annual growth over the four prior years. (Fig. 1) While semiconductor foundries have effectively served the automotive industry over the last decade, future demands are expected to grow dramatically due to the increasing variety of electronic functionality that future vehicles will require. As future automotive electronics systems become ever more sophisticated, specialty foundries will be challenged to apply their advanced process technologies to meet automotive-centric applications. Moreover, they must assure that their stable manufacturing processes satisfy the most demanding quality/reliability criteria. Specialty Foundry Attributes to Serve Automotive Industry Semiconductor devices destined for automotive applications must meet stringent specifications because of the harsh environments they must endure. The need for uncompromising IC reliability in is especially evident in automotive subsystems that control vehicle operation and safety features. When it comes to choosing a specialty foundry to process and make automotive ICs, there are certain attributes needed to ensure successful outcomes. For starters, the specialty foundry should offer an overall automotive-centric strategy for reducing costs, improving reliability, simplifying design complexity, and accelerating time to market. In addressing Zero-Defect expectations, the specialty foundry should be fully prepared to provide the following: - AEC-Q100 certification/support - ISO/TS-16949 certification/support - Robust Technology and design kits - Rigorous Process Qualification Criteria - Closed-Loop Continuous Improvement Plan (CIP) - Tight Defect Management and Yield Performance - FMEA (Failure Mode and Effect Analysis) - 15 Years' Record Retention Record (Minimum) - Fully Equipped Failure Analysis and 8D Problem Solving Let us now explore in greater detail how these attributes come into play as a specialty foundry might best position itself to meet the demanding criteria of the automotive industry.

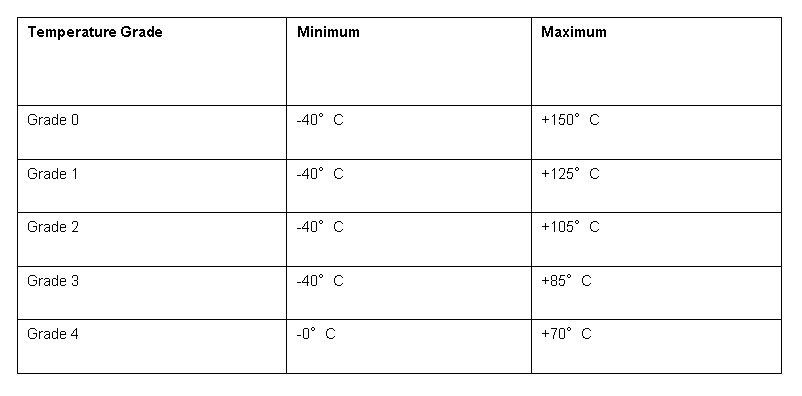

AEC-Q100 Support with Rigorous Process Qualification Criteria The Automotive Electronics Council defines AEC-Q100 as a stress test qualification for ICs. The ISO/TS-16949 establishes international part-qualification and quality-system standards.. Earning these certifications is a prerequisite for a specialty foundry to serve the automotive industry. In semiconductor manufacturing, there are two levels of qualification, one for product, and another for process. Product qualification parameters such as those specifying operating temperature ranges are shown in Table 1. Not surprisingly, foundries are particularly focused on process qualification.

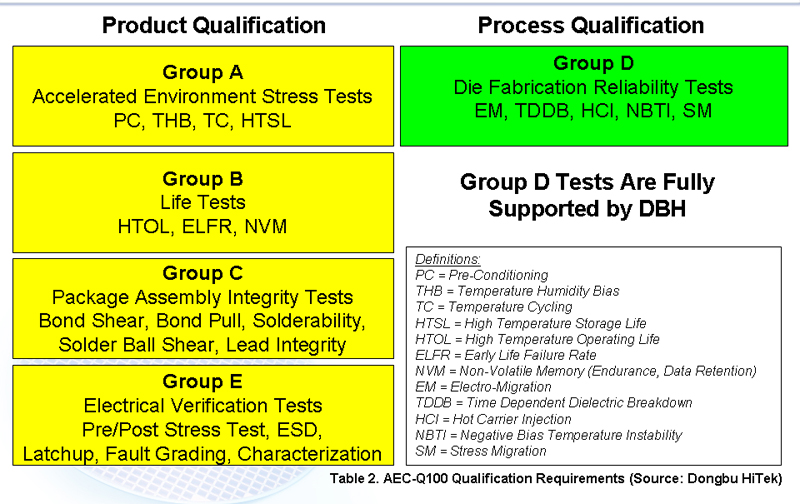

As shown in Table 2, product qualification requirements are categorized in five individual groups: (1) Group A: Accelerated Environment Stress Tests, (2) Group B: Life test, (3) Group C: Package Assembly Integrity Tests, (4) Group D: Die Fabrication Reliability Tests, and (5) Group E: Electrical Verification Tests. Among those five categorized groups, the major foundry focus is on Group D, which contains various wafer level tests such as EM (Electro-migration), TDDB (Time Dependent Dielectric Breakdown), HCI (Hot Carrier Injection), NBTI (Negative Bias Temperature Instability) and SM (Stress Migration). Significantly, close collaboration between a foundry and its customers is essential to producing robust products that meet time-to-market deadlines. Providing full foundry technical support during various test stages (Groups A, B, C, and E) is absolutely critical. In the analog and high-voltage area, where the development of many power management ICs takes place, the most frequent product qualification issues relate to ESD and "latch up." Specialty foundries best positioned to resolve these issues have invested adequate resources to build an in-house ESD Laboratory and a responsive consulting organization.

Table 3 charts the three major categories for automotive process qualification: Quick Wafer Level Qualification (Q-WLR); Full WLR; and Product Level Reliability. The main purpose of Q-WLR is to quickly check device reliability during process development prior to finalizing device structure and process condition. Since this is the preliminary check before the full process development with qualification, the number of sampling sizes may be minimized. Key items to be measured during this step are (1) Reliability of passive components (e.g. capacitors and resistors, (2) Reliability of MMOS Hot Carrier injection and Interconnect, and (3) Integrity of unit processes such as Inter-Metallic Dielectric (IMD) and Inter-Layer Dielectrics (ILD). Full WLR is more extensive than Q-WLR, which relates to Intrinsic Component Level Reliability tests for Transistor Reliability, Gate Oxide Integrity and Electro-Migration in both contacts/vias and metal interconnects. In evaluating Transistor Reliability, a critical qualification is Safe Operating Area for both Electron and Hot Electron to ensure that Breakdown performance is satisfied at various bias voltages. Product Level Qualification sets key electrical parameters at the package level. Covered are ESD and latch-up as well as various stresses with accelerated conditions such as HTOL, EFR, THB and HTS/LTS.

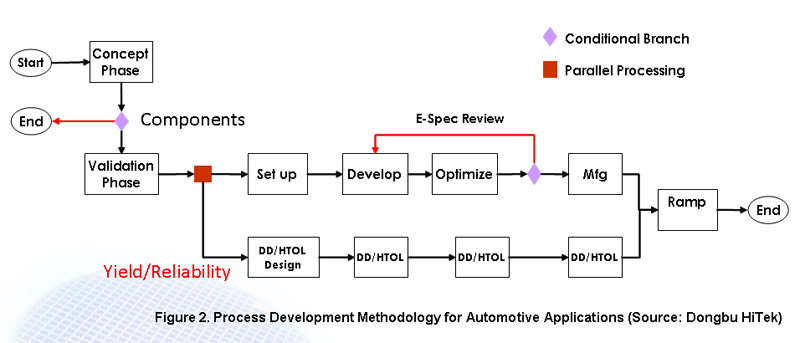

Robust Technology and Design kits As the onset delineated in Figure 2, a robust Process Development Methodology (PDM) must be to: (1) shorten technology development time while maintaining high quality with parallel approach in process set up and verification in each step; (2) create more accountability through a sign-off procedure; (3) standardize the development process; (4) provide real-time oversight by a quality management steering committee. Ideally, a robust PDM encompasses five main phases: Concept, Validation, Development, Manufacturing Readiness, and Ramp up, with each phase including a sign-off/toll-gating step. Just as important as implementing a robust PDM is the need to provide top accurate Process Design kits (PDKs) to help designers navigate areas such as (1) silicon extracted model parameter at 150°C, (2) design library (Standard cell, I/O and Memory Compiler) characterization at 150°C with full characterization report, (3) full qualification of various design IPs (e.g. macro) at 150°C. (4) various design manuals/guidelines including one for ESD.

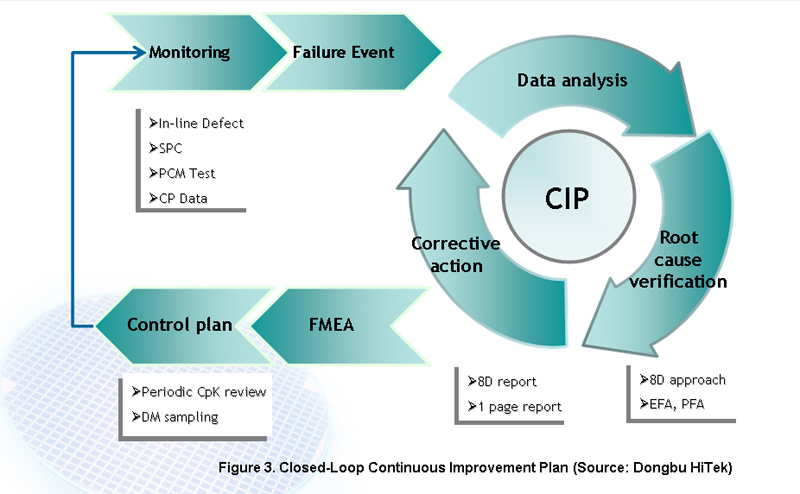

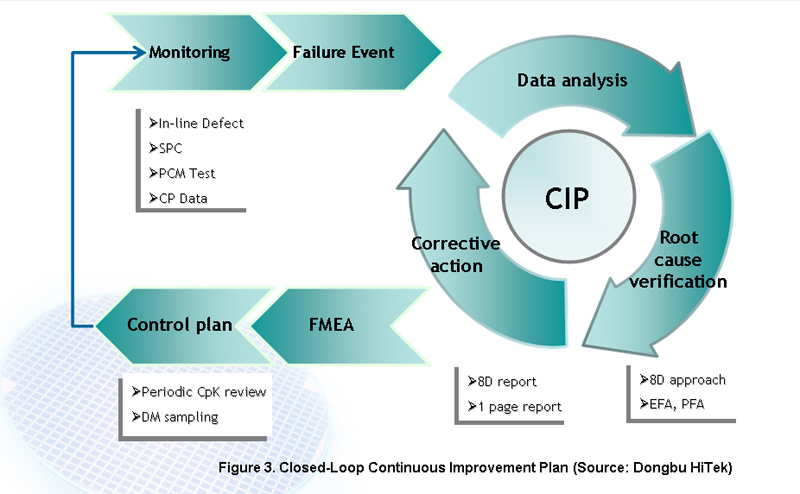

Closed-Loop Continuous Improvement Plan (CIP) Plus Tight Defect Management The final step to ensure specialty foundry success in supporting the automotive industry is to implement a continuous closed-loop improvement plan (CIP). As shown in Figure 3, a well formulated CIP closely aligns with continuous defect reduction (in fulfillment of Zero DPPM) to maximize product yield and minimize the risk of parts failing after they leave the wafer fab. CIP execution based on periodical process performance (CpK) review and in-line monitoring is essential. For in-line monitoring, the specific Defect Density TEG (test element group) must be used as it contains various sizes/shapes of key components, so called an Integrated Yield Module or IYM), plus a fixed-size SRAM, a powerful tool for eradicating hard defects from the Fab. Often a 24 hr burn-in requires identifying the source of soft defects which are not detected during the SRAM function test. On the other hand, the IYM enables a secure component level of parametric stability. Finally, the importance of collaborating closely with customers cannot be stressed enough. A specialty foundry must work closely with its automotive IC customer to achieve mutual success. Data Analysis, Root Cause Verification and Corrective Action are among those critical areas that must be shared to enhance overall process capability even during manufacturing stages Other Specialty Foundry Considerations Due to the long anticipated lifetime of automotive ICs, a specialty foundry should provide Record Retention for at least 15 years. However, critical documents such as customer specifications and those relating to qualifications and contract reviews should be maintained in perpetuity. Operating a fully equipped failure analysis laboratory is another way to meet Zero DPPM goals while expediting problem solving during product development. www.dongbuhitek.com