Author:

Masoud Beheshti, Director of Product and Marketing Strategy, Texas Instruments, Power Supply Solutions

Date

07/24/2012

The intricacies of power design are not conversation pieces for electronic-product consumers. Nor should they be. Consumers care about visible signs of power design in the product, including the size of the power adaptor, how hot the product gets while in use or at rest, runtime, and battery lifetime. The journey from source to load is not free Power's journey from a source to various points of load in the system is a necessity. It is also an opportunity for creativity and innovation. This is a concept that consumers are fairly familiar with in other domains. When we fill up our gas tank and pay cash, we know how the gas mileage of the vehicle determines the next time we need to reach into our pocket again. Of course, our driving habits play a role, but all things being equal, ultimately the vehicle design determines what we can expect. When it comes to electrical and electronic products, the direct correlation between cash and mileage may not be as obvious. However, consumers have come to appreciate the relationship between power use and waste to their electric bill each month. Factors such as leaving the lights on unnecessarily or setting thermostats extremely low at the height of summer, contribute to power waste. However, ultimately, it is the product's power design that determines its efficiency and how much power is wasted. Several key elements drive efficiency performance in these products. These include but are not limited to:

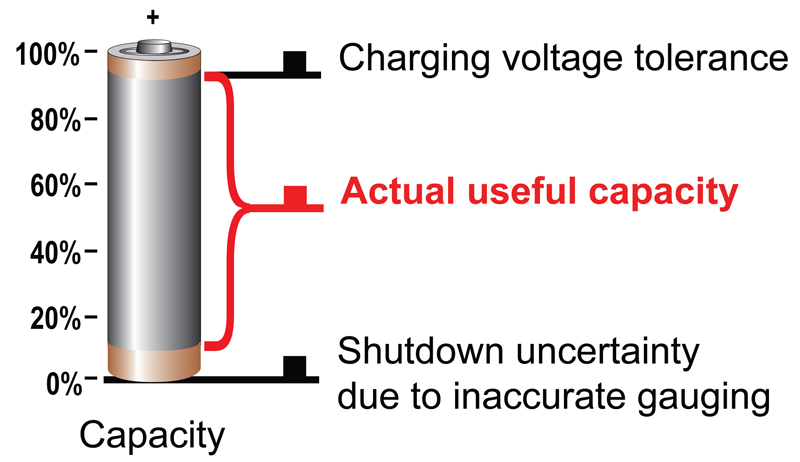

Can I make one more call? As consumers, we have come to not only love, but depend on portable devices such as smartphones, tablets, and ultrabooks. Similar to a car, when the gas tank is full we are happy and worry free. As the needle moves closer to empty, the anxiety level starts to rise: Can I make it to the next gas station? Or in our case here, can I make that one urgent call, or can I finish watching the last 10 minutes of the movie before the flight lands? System efficiency is a major factor but so too is the battery management—an all-encompassing term that covers many aspects of how we use and treat advanced rechargeable batteries:

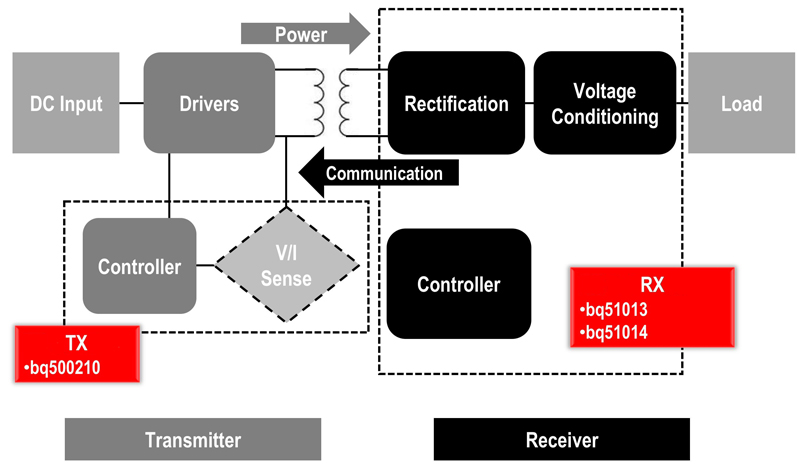

It's all about ease-of-use Ease-of-use is a critical differentiating factor in the consumer space. New technologies now enable OEMs to extend this trait to the power area. One great example is energy harvesting. This technology allows the product to seamlessly take power from alternative energy sources such as solar, vibration, heat, and RF. Advancements in both the harvesters and power converters are increasing the use and reach of this method well beyond the traditional solar cells calculator and watches use. Another exciting area is wireless power. Also known as inductive or contactless charging, it enables the consumers to charge their portable products without the hassles of cables and connectors and by simply placing the device on a charging surface. To make this technology more consumer-friendly, a considerable amount of work and collaboration has been applied to standardization. Standardization makes various devices interoperable, so various makes and models of portable devices, from phones to digital cameras to Bluetooth headsets, charge using a common charging pad. Many industry participants, including Texas Instruments, have been active in the WPC (Wireless Power Consortium). The WPC first published a Qi-standard specification in 2009 and many OEMS are now offering Qi-compatible products. Qi technology includes an inductively coupled power circuit that dynamically seeks resonance, allowing the primary supply circuit to adapt its operation to match the needs of the devices it supplies (Figure 3). It does so by communicating with each device individually in real time. This allows the technology to determine power needs and factors such as the battery or device age and charging lifecycles. Qi technology supplies the optimal amount of power to keep a device at peak efficiency. www.ti.com