Naturally, when specifying an AC/DC supply for a new project, one needs to select a product with the right output voltage and current rating, as well as input voltage range. But it goes much deeper than this in reality. There are two major issues to be addressed: What is the power-distribution topology that will be used? And what are the thermal and supply placement/mounting options? Without going deeply into the internal topologies of the AC/DC converters, there are some commonly used design approaches, but to the end user, the supply can be considered simply as a "black box" with input, output, and performance attributes. If all that's needed is to supply a single DC rail to a single PC board from the AC supply, this is a relatively easy situation. For example, it may be required to deliver 12V DC at 20 A (nominal 240 W) to a mid-size board, with all further power needs handled locally on that board. Many applications, however, need that single voltage across two or more boards, or need different voltages (and currents). Right there, you have the choice of one larger supply, or multiple smaller ones, Figure 1.

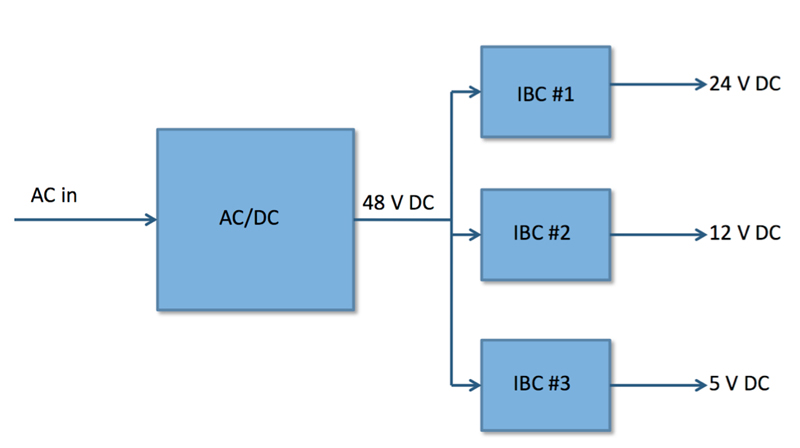

Many applications use multistage-power-distribution approach, where the AC/DC supply feeds one or more intermediate bus converters (IBCs), which in turn transform the DC voltage from the AC/DC supply into lower-voltage DC rails. For example, individual IBCs may take 48 VDC and provide 12 V DC, 5V DC, 3V DC, and other voltages needed by the circuitry, Figure 2. If the system uses IBCs, the decision for which AC/DC converter would be needed is again simplified. In most designs, there is only a single intermediate voltage, such as 48V DC or 12V DC (some more complex systems use a variety of IBCs supply rails. Therefore, the focus should be on finding an AC/DC supply (or supplies) which provides the desired intermediate rail voltage(s), at sufficient current. Efficiency Efficiency and the thermal load dissipation have major effects on design and placement, as well as operating and life-cycle costs. Many regulatory standards now mandate minimum supply efficiencies, with the specific value depending on the nominal wattage rating of the supply. The good news is that almost any supply from a reputable vendor will meet these standards. But it is important to make sure that the supply is certified for the countries in which the product will be used, since these standards are not fully harmonized. Given that almost all new AC/DC supplies have efficiency in the 85 to 95% range, why should we be concerned about exact figure? After all, today's switching supplies are a big improvement over the 50-60% efficiency of older, linear (non-switching) supplies. Here's why: even a few percentage points can make a big difference, three ways. Using an example of a casino floor of several hundred gaming machines: • First, we need to supply that extra power, which adds up and is an ongoing cost. • Second, we need to get rid of the heat that the supplies generate; again, an ongoing cost. • Finally, heat is the killer of electronics, and even a few more degrees can severely shorten the life of a supply—which means field replacement, labor costs, and a product not generating revenue for hours or longer. It is important to note that a properly designed and built supply and operating within its rated specifications has a MTTF (mean time to failure) of several hundred thousand hours—but a 10?C increase can cut the MTBF in half.

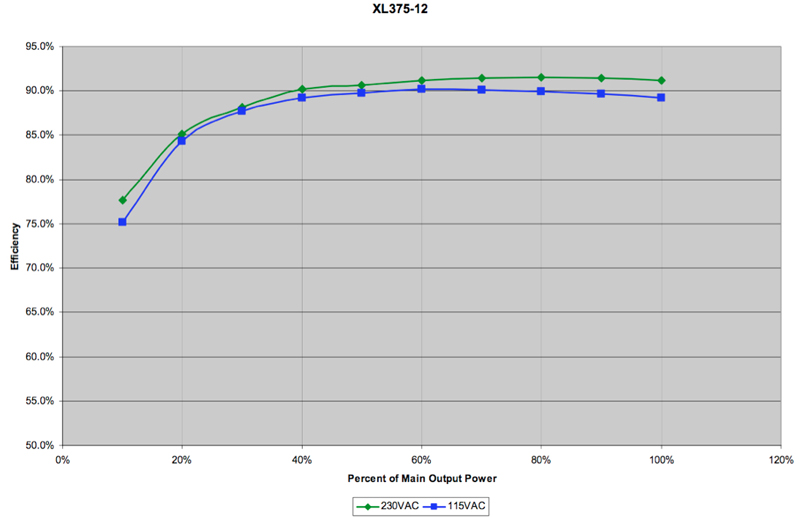

So what is the solution? Choose the highest-efficiency supply you can afford in BOM cost, and also factor in the operating and lifecycle costs. But be careful with efficiency numbers, as they are not constant across the entire load range. Most vendors provide an efficiency vs. load graph, which shows the supply's performance from light load—say, 10%—to full load. Supplies usually have an efficiency "sweet spot" at around 85-95% of their full current rating, Figure 3. Understand the position on the load curve, and the product's duty cycle, to decide how much efficiency is needed and the benefits of the cost of additional efficiency. A supply that is operating mostly at mid-range load (50%) and 85% efficiency, and only occasionally at near-maximum load (90%) but with much higher efficiency of 95%, would cost-out differently than one which is slightly less efficient (such as 93%) at 90% load, but operating at that point most of the time. The up-front cost for a few extra points of efficiency may not be worthwhile or even meaningful, depending on the product's operating modes. Similarly, it is important not to over-specify the supply's size, with the intention of getting greater efficiency and longer life. For example, if we need a supply that can deliver 400W, we would look for a supply that is rated in the 500W range. It could also be possible to get a 1000W supply, which would certainly have more capacity than needed. However, it would be less efficient than a 500W supply, in paying more for the supply itself, and the operating costs will be higher. Location Where it's located, is a major factor in success. Some supplies are designed and specified for convection cooling alone, and no forced airflow; others assume active cooling via airflow (usually from a fan, but chillers are also used in some cases). Other passive cooling techniques include heat sinks, heat pipes, and cold plates, all of which add to cost and design complexity. In general, having forced-air cooling allows a less-expensive supply design, but one must factor in the cost and reliability of the fan itself. The supply vendor will specify how many cubic feet per minute (CFM) of air, and at what temperature, is needed to push past the supply. Whether using passive or active cooling, consideration of the location and orientation of the supply is important. Most supplies are rated at a defined orientation, and changing this means that heat-generating components will have inadequate airflow (and also heat adjacent components). If there are any questions regarding mounting and its impact on the supply's ratings, this will need to be taken up with the vendor for additional insight. The reality is that supplies tend to be dropped in an available, crowded spot—often next to other sources of heat, such a PC boards with hot processors, or motors. The ambient temperature expected can be much higher than what the PSU actually encounters, so it is vial to clarify where the dissipation of the non-supply part of the system is going and how it gets there. This may have to take this into account as part of the cooling strategy or supply-rating assessment. Electrical specifications Now, we can focus on the electrical specifications. Start with the AC side of the AC/DC converter, of course, and a straightforward question about the AC line's nominal value and range. Will the AC line be only 120 VAC only, 220 VAC only, or is it required to handle both nominal lines with a single supply? In general, supporting only one AC range results in a less costly supply, but the difference is fairly small with most supplies. Some vendors do not even offer units for a single line range, since it's a logistical headache to design, qualify, and ship two similar supplies. The bigger question is the line tolerance needed. The wider the tolerance around the nominal value—5%, 10%, or more—the more difficult the supply challenges, especially when it is called to supply maximum output at minimum line; note that a full-range supply could be specified for 90 to 264 VAC. Also, on-going line voltage fluctuations make it more difficult for the supply to maintain its regulated output, even if the load is not changing. As with most engineering designs, it's these cases of operation that require a careful study of the vendor's data sheets, and see if max/min specs are maintained under worst-case conditions, or only at nominal points. Moving on to the DC side, look at required voltage(s) and associated current rating(s). Do check if the supply's output regulation meets design requirements—that's the ability to maintain the nominal output within tolerance, despite shifts in the current being drawn from the supply. Most vendors offer screw terminals for the DC output, but connectors are also available as standard options. Screw terminals reduce costs of interconnection cables, but require more labor in final assembly of your product and are prone to wiring errors. Other features need to be checked are on the regulatory compliance. The major ones cover efficiency; power factor correction (PFC) (how much the supply shifts the line current with respect to voltage); safety issues such as isolation and fault modes; RoHS (reduction of hazardous substances); and EMI (electromagnetic interference). Check that the vendor meets the applicable standards and certifications; as nearly all do. If not, just go to another vendor because there's little one can or should do if the supply falls short in any of these areas. Even if you something could be done, there's no way to qualify the fix and get certification, so any engineering effort would be wasted.

Nearly all supplies, such as the XL375 series from N2Power (see Figure 4), incorporate standard protection features such as overvoltage protection (OVP), output current limiting and shutdown (crowbar), and thermal shutdown. This supply offers shut down on command, loss of input power, or whenever excessive loads or temperatures are sensed, and provides the host system with warning of an impending shutdown, to enable it to perform housekeeping before power is lost. Finally, it is important to check the ability of the supply to handle line transients. All supplies can do this to some extent—there is an IEC transient-test waveform, of course. But your application may see transients that are greater than that, due to nasty nearby loads (relays, motors), lightning, and other factors. You may want to add additional transient protection via a low-cost passive component on the AC mains, ahead of the supply's input. Conclusion Today's AC/DC supplies are remarkably efficient, compact, versatile, and rugged, while incorporating complex control strategies, algorithms and protection. At the same time, they meet a wide variety of performance and safety standards. First decide what supplies are needed and where—both functionally and physically—it will be possible to take the next step of finding a vendor and specific models that meet the project's needs and cost targets. N2Power