Despite the best intentions at the outset of an electronic product's design, it is commonplace for the power supply specification to evolve during the process and to only be finalized late on. At this point, it's not uncommon to realize that the remaining physical space cannot accommodate an industry standard power supply, or that such units cannot fulfill other technical requirements. Obsolescence also creates demand for non-standard power supplies. Power supplies may fail in equipment that is otherwise perfectly functional and economical refurbishment can only be undertaken if a replacement power unit can be found, or developed. In both of the above circumstances, designing a fully customized power supply in house, or contracting the work to a third party are potential options. However, both routes present technology, cost and time-to-market risks. This is particularly true with grid connected power supplies that have to meet stringent safety and EMC standards in order for the end equipment to meet the requirements of regulatory authorities such as TUV and UL. The option to create a simple AC-DC input then populate a printed circuit board (PCB) with standard DC-DC modules, sometimes called "bricks", may look straightforward. But even this apparently simple approach is fraught with challenges. Why else would brick manufacturers offer training courses to help designers define requirements, avoid instability through source impedance control, minimize EMI, ensure effective decoupling, improve load regulation and develop effective parallel arrays? Overcoming these technical challenges takes knowledge, experience, and considerable design time.

For a growing number of companies, the solution to creating customized power within acceptable time and cost limits is to take the semi-custom route. In other words, using standard building blocks as the basis for power supplies which meet specific requirements with respect to form, fit and function. As mentioned earlier, doing this in house requires experience and resources. The electrical design must meet technical requirements in the most economically viable way. Electronic design automation tools are then needed for schematic capture and PCB layout, mechanical layouts need to be modeled in 3D and thermal imaging is required to identify potential hotspots. Access to safety and EMI test equipment, and the knowledge of how to use it properly are essential. The process for designing a reliable semi-custom power supply needs to be the same as that for a standard unit. The typical process adopted by XP Power is shown in Figure 1.

After receiving a definition of requirements, the company draws up a specification proposal and compliance matrix for its customer. These are reviewed and approved before a detailed project plan is prepared. Design is always an iterative process, so a detailed "Query Log" is maintained to provide a record of decisions taken along the way. Prototype testing is followed by provision of full design verification test results. These include results of temperature cycling and other accelerated aging tests, where appropriate. A detailed design review process is fully documented throughout the development of the product and a production test specification is agreed before it goes into full production. The end result is a customized product that has been created to the same rigorous standards as a standard power supply.

Customization can be as simple as changing connectors. This might involve just removing a vertical connector and replacing it with a horizontal one. Other simple modifications include customizing covers with different fixings or producing custom wiring looms to reduce assembly time for the end equipment. Some of the most common requirements for more comprehensive customization are:

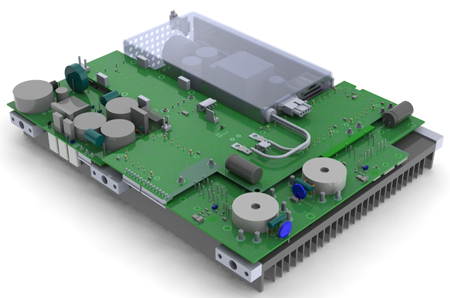

Figure 2 shows a customized power supply for a portable, secure, communications modem used in the field. It was developed around three standard, 150 Watt, DC-DC converters, type MTC150. XP Power added a discrete, 600W AC-DC boost converter with active power factor correction, two DC input conditioning modules, a further commercial DC-DC unit to create a 28V bus, and a 300W DC-AC inverter module. The resulting unit has a 28V battery input, a wide-range input of 10-36V DC, and a universal 90 to 264V AC input. The outputs are 28V DC, 12V DC, and 110V AC. The power supply was designed in a low-profile form factor with integral heat sink. This unit is a good example of a very heavily customized product with custom electrical and mechanical elements built around standard modules.

Agency qualification (UL, TUV etc.) is required for most grid-connected power supplies. The cost and time taken to obtain qualification for end equipment is an important consideration so it's vital that the risk of failure is minimized. Standard power supplies will have already gone through rigorous approvals processes but it is essential to ensure that customized units have been tested to the same standards. A supplier of customized power solutions must be able to provide test documentation that gives a high level of confidence with respect to agency requirements and customers should expect the same level of warranty on the customized power supplies as would be applicable to comparable standard products.

The balance of quantity and complexity determines the economic viability of semi-custom power supply design. Simple changes can be applied to relatively low cost products for quantities in the low hundreds. Large programs involving complex customization are only likely to be viable where the final value of business to the power supply manufacturer is in excess of $50,000. Full custom design has a much higher economic entry point and few products will see the light of day in less than 6 months. In contrast, prototype semi-custom power supplies can typically be created in 6 to 12 weeks using field-proven, standard building blocks. www.xppower.com