Author:

Tom Curatolo, Principal Field Applications Engineer, Vicor

Date

01/28/2021

Click image to enlarge

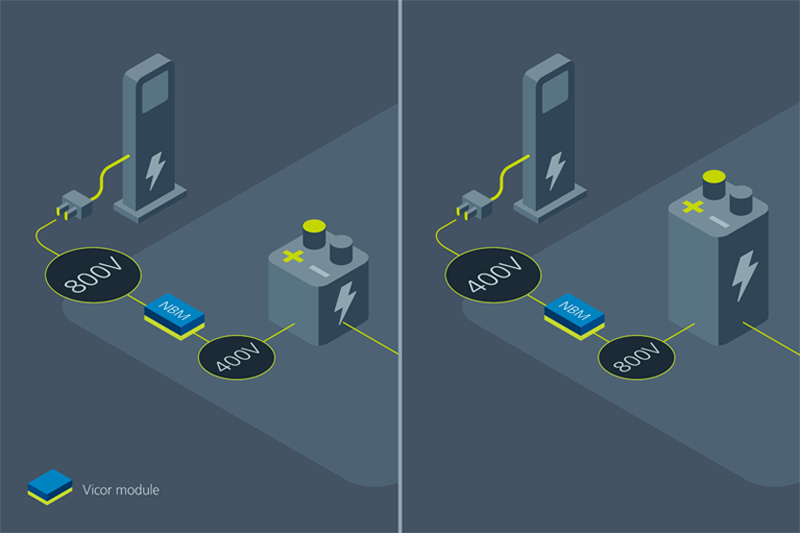

Figure 1: To make EVs and charging stations compatible, independent of whether they use the same voltage, the power delivery network uses a Vicor non-isolated fixed-ratio bus converter module (NBM) to convert either 800V to 400V or 400V to 800V at 6kW. This high-efficiency, high-density, scalable solution enables EVs of different battery voltages to utilize the same charging stations

Fixed-ratio convertershave power density, efficiency and flexibility attributes that can enable higher-performing power delivery networks (PDNs). This is true even when faced with wide-output-voltage-range power sources, such as batteries or renewable energy sources. Unlike more popular, mainstream regulated DC-DC converters, fixed-ratio converters allow designers to architect and optimize their PDN for higher system performance. When separating the conversion, isolation and regulation functions enables appreciable performance gains and major end-system benefits.

Advanced power delivery networks in automotive, light electric vehicle (LEV) , robot, UAV and industrial applications are moving to higher-voltage power sources of 100V, 400V, 800V and higher SELV distribution levels at 48 – 60V to enable the higher power that many modern day systems are demanding. Many of these systems utilize batteries, renewable energy and fuel cells as the main power source for the PDN and have one challenge in common: widely-varying output voltages. Because of this variation, the most common converter used for high-voltage, wide-range power sources is an isolated, regulated DC-DC converter, designed and built as one functional block.

However, a DC-DC converter does not have to perform conversion, regulation and isolation in one functional block. In fact, each of these functions costs the converter points of efficiency that translate to higher power losses manifested as heat, the primary factor determining the achievable power density of a DC-DC converter solution along with its cost and reliability. As system power levels increase into the many tens of kilowatts, power loss becomes the dominant challenge to power converter size and weight. Thermal management also adds significant size and cost to the power conversion stage.

An alternative architecture

Most systems require isolation in the high voltage areas of a PDN for safety reasons, but the conversion and regulation functions can be separated. Once the high-voltage PDN is down-converted by the fixed-ratio converter to the desired SELV voltage (determined by the converter’s K factor), the decision points for the architecture are where best to further convert and regulate to manage power delivery for the system loads. Due to power level increases within applications such as high-performance computing and electrified vehicles, the use of 54V and 48V, respectively, as the SELV distribution voltage level, instead of 12V, is becoming more popular. Due to the higher load currents, these higher voltages offer significant distribution power loss reductions (I2R) and efficiency improvements, plus the weight and cost benefits of using smaller cables, wires, connectors and PCB copper power planes. However, the key to using fixed-ratio converters in the front-end architecture in these systems is the capability of any downstream intermediate converter and PoL (point-of-load) regulator, to manage a wide-ranging voltage centered on these higher SELV levels. Buck and buck-boost regulators with zero-voltage switching (ZVS) topologies have advantages due to their higher efficiencies when converting and regulating higher voltages.

Consider three applications where significant performance gains are made by separating these three functions:

a) Automotive EV charging application

b) Harvesting robot application

c) UAV application

Electric vehicle charging: non-isolated high-voltage conversion

The electric vehicle (EV) market increasingly uses 800V and 400V batteries as the main power source, which, because of their rapid-charging capabilities at these voltages, supports wider acceptance and adoption of EV technology. Charging stations are being deployed more widely but they do not take into account both battery voltages. Automobile manufacturers are developing onboard charging systems that can either up-convert a 400V station to the vehicle’s 800V battery or down-convert 800V to 400V for compatibility and fast charging. The power levels for these onboard converters range from 50 to 150kW. Since the charging station has an isolated and regulated DC output and the 800V or 400V battery has an isolated high-voltage DC converter for downstream systems, isolation and regulation are not required for the bidirectional 800V-to-400V converter. Using a high-switching-frequency topology, efficiencies are nearing 99.3% , which significantly reduces the size and weight for this type of converter.

Harvesting robot: isolated and non-isolated conversion

Click image to enlarge

Figure 2: To handle the wide range of loads while conserving battery power, a harvesting robot power delivery network uses a Vicor fixed-ratio bus converter module (BCM) to generate a 48V bus that minimizes losses associated with lower-voltage buses. Power is then efficiently delivered to loads with fixed-ratio or regulated point-of-load converters such as Vicor NBM, PRM, ZVS buck and ZVS buck-boost regulators

Harvesting robots are large machines and can require up to 20kW of power, typically supplied by an 800V battery. The PDN efficiency which translates to longer operational up-time between charging is important to this class of applications. An isolated bus converter or fixed-ratio converter is used to down-convert the high voltage to an SELV level such as 48V, which offers the highest distribution efficiency for cables and connectors. Bus converters can be easily paralleled to scale the front-end power conversion stage and provide significant design flexibility. Direct 48V conversion and regulation can be achieved to the various system loads with high-performance ZVS buck boost and buck regulators. For 12V loads, such as the system’s CPU motherboard, a 48V-to-12V non-isolated fixed-ratio converter is the highest-efficiency and most power-dense option. Regulation is then achieved by the multiphase 12V buck regulator stage to the PoL.

Tethered UAV: SELV boost conversion to high voltage and buck conversion to low voltage

Click image to enlarge

Figure 3: To dramatically reduce the diameter and weight of the tether, the power delivery network uses a Vicor fixed-ratio bus converter module (BCM) to step the tether voltage up to 800V. As with other PDNs, the 48V bus is used locally to minimize losses, both on the ground and in the air. The BCM is also used to isolate and step down the rectified output from a single- or 3-phase AC supply to 48V

Tethered drones are used by security, fire and rescue teams for fixed observation, communication and lighting purposes. A bidirectional fixed-ratio converter can enable a very efficient flexible design that allows the use of an SELV battery power source while still minimizing tether size and weight to maximize up-time and payload. In this class of application a K 1:8 bus converter (used in reverse) boosts the 48V to 384V to deliver power along the tether and reducing tether thickness and reducing losses (I2R). The same K 1:8 converter is also used onboard the UAV, to down-convert the 384V to 48V for the onboard electronics and UAV rotor system. This PDN maximizes efficiency and the power density (size and weight) advantage of fixed-ratio converters and benefits the drone by freeing up space for payloads. In future applications a K 1:16 will be used to boost 48V to 800V in order to increase tether length for higher-altitude operation while further reducing tether thickness and weight.

Efficiency and power system density of a PDN is critical to performance when measured in up-time, charging time, distance travelled and payload capacity, to name a few important features for the automotive, robot and UAV markets. PDN performance can be increased as clearly demonstrated with fixed-ratio converters even when using wide-ranging power sources such as batteries. In these and other applications, the isolation barrier and voltage regulation functions can be carried out upstream or downstream, taking advantage of higher-voltage distribution in the network to reduce the size of cables, connectors and copper power planes on system PCBs. The PDNs shown here are examples of how fixed-ratio converters used in conjunction with high-performance ZVS regulators can help customers with product innovation and deliver higher-performing solutions and a competitive advantage.