Author:

Howard Self, Program Manager - Cleber Angelo, Medium Voltage Global Outdoor Product Manager, ABB

Date

09/10/2012

A power industry consultant recently asked for assistance solving a reliability problem for a municipal utility. The utility had recently experienced disturbances on its system, negatively affecting one of its industrial customers. The customer connects to an old portion of the city's distribution grid that requires upgrading, but due to budget constraints, an upgrade is not currently an option. The city serves this customer from two 46 kV to 8.46 kV substations (Figure 1). The two overhead 46 kV circuits are several miles long and are susceptible to the challenges of overhead distribution systems, including lightning strikes. The consultant and the utility reviewed the service requirements and determined the need to isolate a fault and then transfer to an un-faulted source in only a few cycles. Their requirements also dictated the use of outdoor circuit breakers or pole-mounted reclosers. The city's existing communications infrastructure included a high-speed fiber network available at all subject locations and available for protection or control when required. The utility operates with the two main 8.46-kV circuits closed, and a transfer-tie breaker open (Figure 1). Any disturbance on either 46-kV circuit severely affects the utility's equipment by dragging the 8.46-kV bus voltage to unacceptable limits. The rotating machines on the customer side decouple if the 8.46-kV bus voltages fall below 0.85 kV nominal for 10 cycles. To support utilities' grid enhancement efforts, ABB recently established a Distribution Automation Verification Lab in Raleigh, NC as part of its new Smart-Grid Center of Excellence. This lab enables utilities to verify functionality, interoperability, and operational expectations for distribution-grid management subsystems, including verification of non-ABB assets. In the ABB verification lab and demonstration area, there are five 15-kV 12.5-kA reclosers equipped with recloser protection-and-control relays, and two 15-kV 25-kA outdoor circuit breakers equipped with feeder protection-and-control relays.

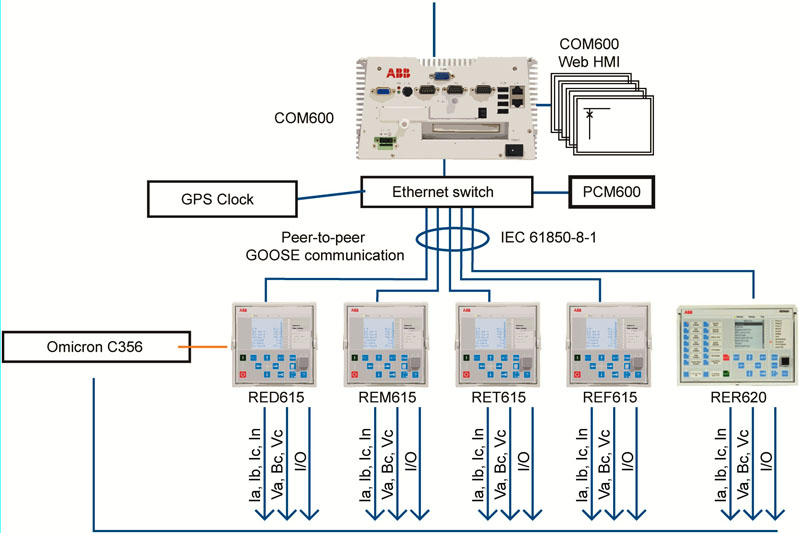

All of the relays have secondary phase-voltage inputs (Va, Vb, and Vc) and phase-current inputs (Ia, Ib, Ic, and In) connecting back to a central test panel where an Omicron C356 test set can inject precision analogs signals. Inputs and outputs also wire back to the central control panel from each IED (intelligent electronic device) for monitoring circuit breaker position, triggering the test set, and allowing for input triggering on all IEDs simultaneously. A substation computer or a communication gateway that emulates the SCADA/DMS (supervisory control and data acquisition / distribution management system) can control the overall system. The overall system configuration replicates the utility's field configuration in a lab environment (Figure 2). One of the project objectives was the accuracy and repeatability of results, and this data was a part of the deliverables expected by both the consultant and the utility. Due to the multiple IEDs used to gather results in these tests, precision timing was critical. To support these requirements, a GPS clock with an SNTP (simple network time protocol) output connected to the network (Figure 2). The IEDs synchronized to the main system clock source within 1 ms time accuracy and several pre-test checks ensured result accuracy. A series of triggers via binary outputs and Generic Object Oriented Substation Events (GOOSE) messages issued on all IEDs simultaneously to validate controlled triggers and to produce the same events across the network to within 1 ms. The performance validation used the SOE (Sequence of Events) records and fault recording data from the IEDs.

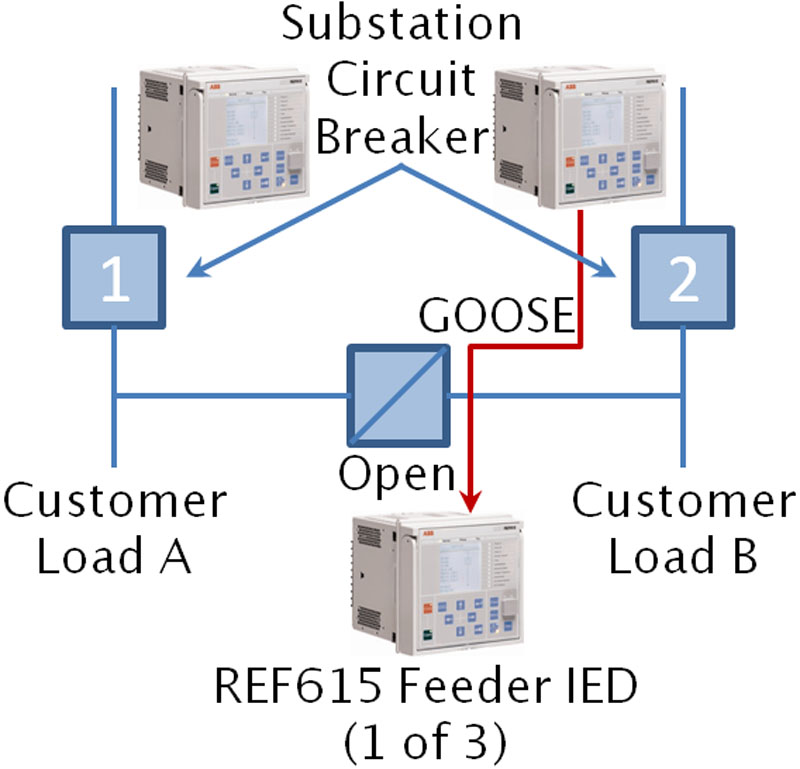

The first test involved the outdoor circuit breakers with protective relays. In addition to protection, control, and metering, each relay has many standard features. These include graphical user-programmable logic, digital fault (waveform) capture, SOE and fault recording, monitoring, load profile, internal web server, and advanced Ethernet communications supporting IEC 61850-8 with GOOSE (peer-to-peer) messaging (Figure 3). Test 1 measured three events: (1) The time for the outdoor breaker equipped with relay to operate under no-load conditions for a manual trip. (2) The time for the remote relay to receive the GOOSE message the auxiliary contact triggered. (3) The time for the outdoor breaker to open upon receiving the GOOSE trigger. The relay's digital fault recorder was set to sample at 32 samples per cycle and record for 50 cycles. Recordings began on rising edge triggers. After triggering events in both relays, engineers combined the recordings for analysis. In summary, the text executed with 58 ms open time, 2 ms GOOSE time, 71 ms close time, and 131 ms total time. The test team conducted this test 25 times to ensure consistent results. GOOSE time stayed very consistent and the breaker open and close times varied by no more than 2 ms. The second test applied fault current of 25 times I nominal to the relay using an Omicron test set. The instantaneous over-current element initiated the trip when it detected the disturbance. The test produced virtually identical timing results from the initiation of trip through complete transfer. The test results consistently achieved less than 8-cycle transfer times under no-load conditions with the outdoor circuit breakers: 58 ms open time, 2 ms GOOSE time, 71 ms close time, and 131 ms total time. Test 3 used reclosers equipped with RER620 multifunction IED controllers in place of the breakers and REF615 IEDs in a topology similar to Figure 3, to determine if the performance could improve. The test executed with 38 ms open time, 3 ms GOOSE time, 41 ms close time, and 82 ms total time. The test delivered improved results from the initiation of trip through complete transfer. The test validated that less than 5-cycle transfer times were achievable under no-load conditions. Engineers tested multiple scenarios using different over-current and under-voltage conditions to ensure the results were accurate and consistent. These tests were the consultant's first exposure to the IEC 61850 Standard and GOOSE messaging capabilities. Upon sharing the test results and procedures with the consultant, he was both pleased and surprised at the ability to initiate actions between devices without the need for physical IO, the ability to monitor GOOSE health, and the ease in which these actions were configurable using the relay's engineering software. Based on the success of the first three tests, the consultant requested an additional test simulating a transfer scheme. The test scenario applied an under-voltage condition to the local recloser, allowing the trip element to issue a trip command and simultaneously transmit a GOOSE message to the remote recloser to close. The results were 50 ms open time, 18 ms GOOSE time, 59 ms close time, and 59 ms total time. The results of the transfer scheme test verify that it is possible to detect and transfer in less than 4 cycles. The system fault detection, isolation, restoration, and transfer scheme was based on the ABB Relion family of relays' native IEC 61850 capabilities with GOOSE, combined with R-MAG distribution outdoor breakers, and GridShield reclosers. ABB