These days, people can't live without cell phones. This is not a monumental revelation to anyone who has been at an airport, a shopping mall, or a park watching their children play. We close business deals, talk to our friends and family, check email, and browse the web while waiting for a connecting flight. But how do we keep them running when on the go? By Tom Karpus, Director of Handheld Systems and Applications Engineering, Semtech Corporation, Morrisville NC The mobile phone has been transformed from what used to be called a "telephone" into a personal communication and data transfer device. All this communicating and data moving takes power, so phone designers and chip companies have poured a lot of effort into squeezing every last mAh (milliampere-hour) of battery life out of each mobile phone function. Talk times and standby times have declined as more complicated, feature-rich products have been adopted by the average user. Advances in phone power management have addressed this issue to some extent, but we still need to recharge our phone batteries when they run out of power. Anyone who travels knows that it's not always convenient to pack a charger. Even if you have the charging adapter packed for the trip, there is no guarantee that you will have access to a power outlet when you really need it. So what else can you do? Accessories are now available that act as a portable charger for just such an occasion. This is a great idea - it's like carrying a portable electrical outlet and charging adapter all-in-one. Such an accessory can utilize different battery configurations to supply the charging power. One simple, low-cost choice is to use two disposable AA alkaline batteries to transfer energy to your phone's Li-ion battery. These batteries are inexpensive, available at any convenience store, and transferable between different devices (providing the option to raid the kids' games when you need to recharge your phone). Depending on the state of your phone battery, this power transfer system could top off the battery or provide just enough power to maintain an important call when your battery is nearly depleted. A typical Li-ion battery charges to a final voltage of 4.2V, so a power supply level greater than 4.2V (typically 5V minimum) is needed to supply the charging circuit. Alkaline battery cells range between 0.8V and 1.6V, so a DC-DC boost converter is needed to boost the supply voltage and regulate the output voltage at the 5V needed to properly transfer charge to a Li-ion battery. The combination of a boost converter with a dual AA battery pack can serve as a 5V power supply for battery charging when a wall outlet or USB supply are not available. A simple circuit can be constructed to provide the 5V needed by the battery charger using a standard DC-DC boost converter IC and some simple external components. Figure 1 demonstrates how this system works. In this example, the boost circuit is contained in an accessory capable of holding two AA battery cells. The 5V output is maintained throughout the duration of the charging operation as the AA batteries discharge. The boost converter used in this example - the SC120 from Semtech - is set to a 5V output by connecting a resistor divider network between the OUT and FB pins.

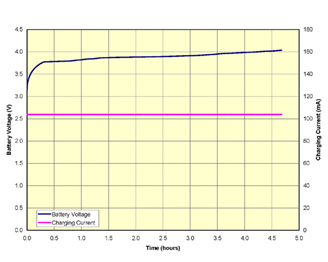

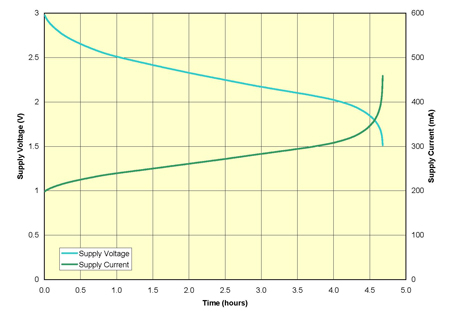

The charger IC typically resides inside the phone or in a charging cradle for removable batteries. Accessories with similar capability use standard USB connectors to attach to the phone charging system. The phone should limit the charge current internally to 100mA - the standard for low power USB charging. The fast charge current in this example is set to 100mA to illustrate charging performance under these conditions. Charging is terminated when the current into the battery drops to 10% of the fast charge current - in this case, 10mA. Figure 2 illustrates the Li-ion battery voltage and current during the charging process using a 750mAh battery, while Figure 3 shows the voltage and current profiles for the AA 2-cell pack throughout the same process.

Figure 2 demonstrates that normal battery charging occurs. The current is held constant at 100mA and the Li-ion battery voltage approaches 4.2V - the cell voltage at which it is fully charged. Figure 3 illustrates the state of the source batteries as charging occurs. The combined AA cell voltage decreases as charge is transferred to the Li-ion battery, and the battery current increases to maintain the boost output at 5V. In this example, the Li-ion battery was fully discharged at the start of charging, so two AA cells provided just enough power to charge the Li-ion battery to 4V (but not completely recharge it to 4.2V). Variations to this system could be implemented using 3 AA cells or a single high-capacity Li-ion cell as the charging supply. Either supply configuration would be more efficient because they would operate the boost converter with less voltage drop. Their increased capacity and efficiency would also give the charger accessory more available charging capacity, which would allow a complete charging cycle or possibly multiple charges. Of course, more battery capacity translates into higher cost. Regardless of which configuration provides the best cost-benefit tradeoff, it is clear that this DC-DC boost converter design approach provides a simple mobile charging solution for the battery powered products that help make busy lives a little easier to manage. www.semtech.com