Author:

Reported by Joshua Israelsohn, Editor-in-Chief, Power Systems Desgn

Date

11/29/2012

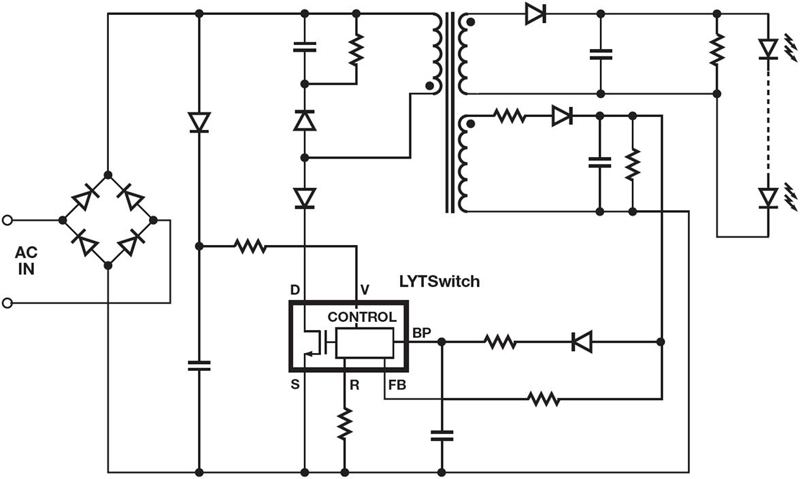

I recently had the pleasure of speaking with Power Integrations Vice President of Marketing Doug Bailey about the company's new LYTSwitch LYT421x and LYT431x families of LED-driver ICs. The LYTSwitch IC design implements a TRIAC-dimmer-compatible LED driver and a PFC (power-factor correction) circuit in a single power-conversion stage (figure 1). Power Integrations has been supplying power-management ICs into lighting applications since 2005 and currently ships about 225 million units annually for such uses. Far from homogeneous, the lighting market makes widely varying demands on power-management silicon providers depending on a device's specific end use. For example, LED streetlamp replacement systems must provide in the neighborhood of 150 W with 94% efficiency and long maintenance-free operating lifetimes of 45 khrs over a wide ambient temperature range. By contrast, devices for interior lighting may only supply tens of watts and have historically delivered efficiencies of 85% operating over a relatively moderate temperature range with expected bulb lifetimes of 15 khrs. However, LED-driver ICs for interior lighting applications must contend with TRIAC-controlled dimmers, with highly variable switching characteristics and behaviors that are famously unfriendly toward the constant-current output control that LED-drivers must provide.

The basic architecture of Power Integration's LYTSwitch LED-driver IC is that of a flyback converter with a current- rather than a voltage-regulated output (figure 2). In this case, the power stage does not require either bulk Aluminum-electrolytic capacitors or an optocoupler in the feedback path. This topology also allows these LED drivers to provide both regulated constant-current output and PFC—not just in a single IC but in a single converter stage. These three enhancements can significantly reduce the cost and size of the complete application circuit while increasing its reliability and longevity. This LED-driver implementation operates at a nominal 132 kHz, reducing the size, cost, and weight of the magnetics. The size reduction is critical in component-height-restricted applications.

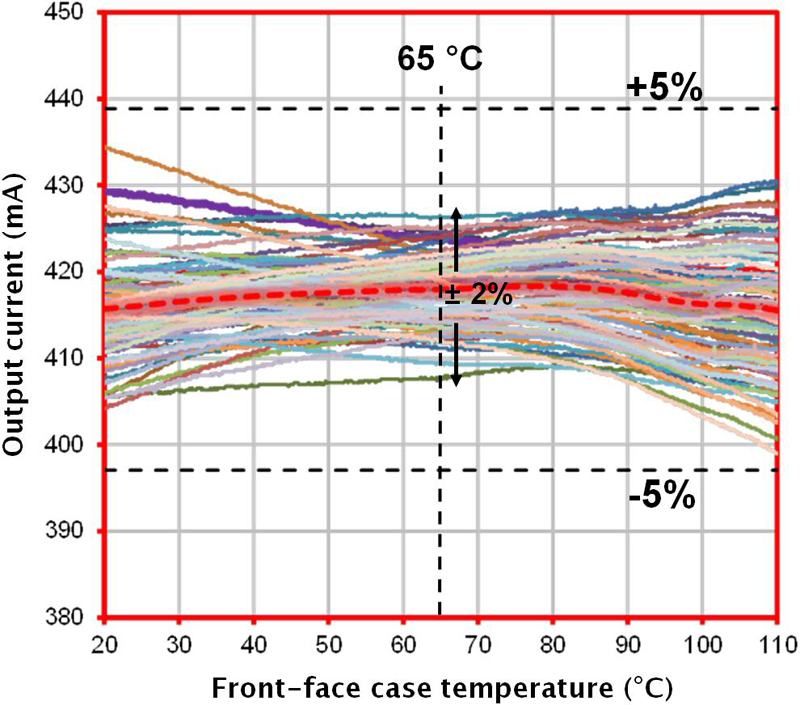

Among the other enhancements the LYTSwitch family offers is a tight tolerance of the constant-current output: Tests of board-mounted LNK4314s indicate less than a ±5% output-current variation over the ?20 to 110 °C case-temperature range and a typical current distribution within ±2% at a fixed operating case temperature of 65 °C (figure 3). These results reflect the combined effect of part-to-part, board-to-board, and load-to-load tolerances. One of the board-to-board variations for which the LYTSwitch LED driver compensates is the parametric distribution in the magnetics, which relaxes the transformer's inductance tolerance. Power Integrations programs the packaged parts at a nominal operating temperature of 65 °C to attain the tight ±2% typical output-current accuracy. The tight output-current tolerance allows bulb manufacturers to reduce the extent to which they overdesign their products: Bulbs are required to deliver a stated minimum lumen output—not a typical or average output. A narrow current distribution results in manufacturers being able to use fewer or lower-power LEDs and operate at a lower average current, all of which increases efficiency and bulb lifetime while reducing size and cost.

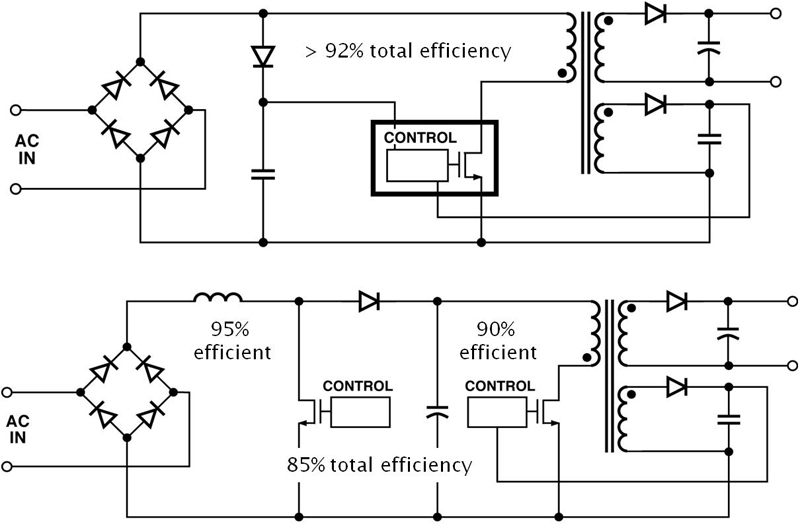

Implementing the current regulator and PFC with a single power conversion stage yields obvious advantages in efficiency, giving the LYTSwitch topology a 7% or more advantage over traditional two-stage designs (figure 4). The single-stage design also benefits reliability and operating lifetime by eliminating the high-voltage electrolytic bulk capacitor between the two stages and reduces size and cost further by eliminating an inductor and MOSFET. A consequence of the single-stage design is that the output includes a line-frequency ripple term. Kept to a reasonable minimum—below 30% modulation—the ripple is generally not noticeable. Inexpensive low-voltage filtering on the converter's output helps reduce the mains-frequency ripple.

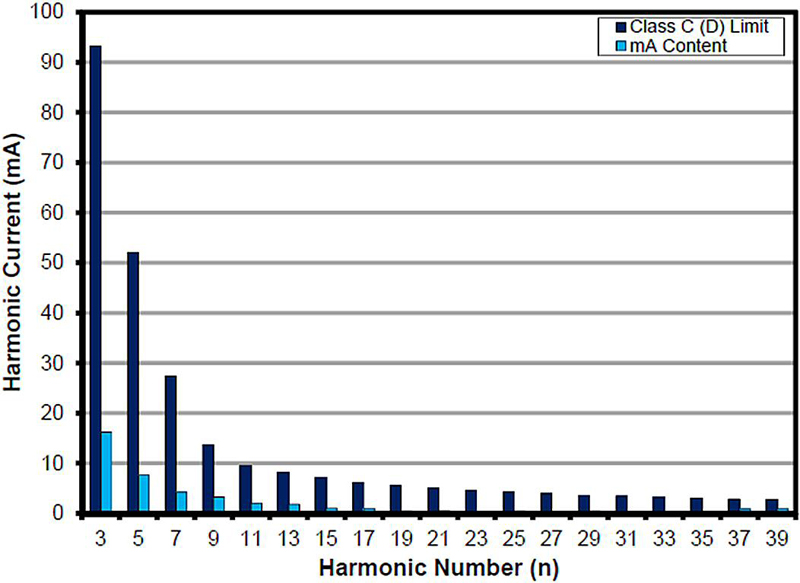

The LYTSwitch LED drivers comply with worldwide standards for PFC delivering a power factor greater than 0.9. The drivers also easily meet EN61000-3-2 class-C and class-D requirements for iTHD (line-current total harmonic distortion) less than 10% in optimized designs (figure 5). Reference designs, datasheets, and product-information videos are available on the company's website. Reference designs include complete application circuits including temperature compensation, active damper and active bleeder circuits, voltage feedback, and overvoltage-protection. The dimmable LYT431x-series ICs are compatible with more than 33 leading edge and electronic TRIAC dimmers and meet the NEMA SSL6-2010 (Solid-state lighting for incandescent replacement — dimming) standard.

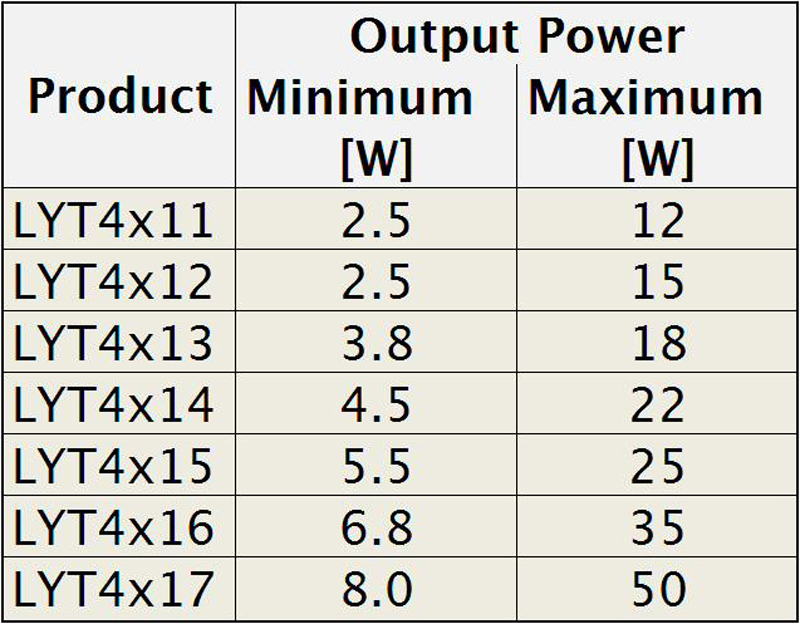

The driver family is available in non-dimmable—LYT421x-series—and dimmable—LYT431x-series—versions. At present, each series is available in seven power levels ranging from 12 to 50 W max (table 1). The devices are available now in the eSIP-7C E package and eSIP-7F L package with prices ranging from $0.70 to $1.60 in 10,000-piece quantities. Power Integrations