Author:

Shadi Hawawini, Senior Applications Engineer; and George Paparrizos, Product Marketing Director, Summit Microelectronics

Date

10/01/2010

Technology advancements over the past few years have generated many new developments that have specifically benefitted the portable medical device market. The focus of such efforts has centered on simplifying data collection/logging and reporting; developing products that allow patients to be monitored remotely; and centralizing patient databases for better and faster healthcare delivery. New portable medical equipment take advantage of the wide adoption of electronic and passive components, materials and software utilized in consumer gadgets, by including features that demonstrate improved reliability, lower cost and faster market entry. As with many other aspects of the medical field, such system designs have their own idiosyncrasies that need to be addressed. Medical devices need to meet certain, stricter criteria for successful market introduction. These include measurement accuracy, product safety, fast charging, longer usable life, and user- and environmental-friendliness. Measurement accuracy is a requirement for ensuring higher accuracy in the sensing portion of the medical device. In most cases, this translates to a need for keeping the medical equipment case temperature within certain tolerances. Higher temperature levels have a negative impact on the sensing precision and may require expensive methods for compensating for potential measurement errors. This is the main driver behind the need for high-efficiency battery charging in such system designs. The graph below demonstrates the power dissipation and temperature levels between a switch-mode and a traditional battery charging solution, while charging a 1700mAh battery.

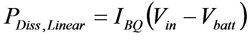

The power dissipation in a linear mode battery charger can be significantly higher, than in a switch-mode battery charge, particularly in cases where the battery voltage is low and the charge current levels are high. The power dissipated for each battery charger type can also be calculated from the below equations. For a switch mode charger, the efficiency will be between 85% and 90%.

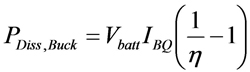

High-efficiency charging can also significantly increase system reliability, since it reduces average ambient temperature levels, which in turn extend the life of other key components and of the portable device itself. Extending usable battery can also be accomplished by reducing frequent and unnecessary charge cycles when the battery voltage is above certain operational levels. Such functionality already exists in some of the modern battery charging solutions on the market and is utilized in other markets where battery charging initiation may be a frequent activity. Product safety is also a very important factor given that many of the portable medical equipment are used by consumers in a variety of environmental conditions. Dynamic adjustment of critical charging and power delivery parameters allows for optimal and safe system operation. Medical equipment can also benefit by real-time monitoring and reporting of charging status and potential charging errors. Such functionality can proactively addresses system failures in a timely manner, which is very critical for patients. The figure below demonstrates an example of a battery charging IC that provides a variety of real-time status and fault information to the system.

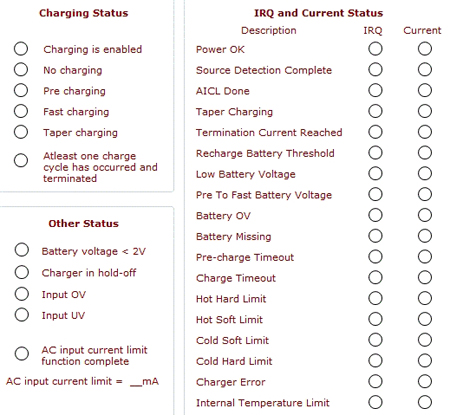

The input voltage to a device and its subsequent protection is also one of the top safety concerns with medical devices in the field. Although a USB port or a wall adapter should be very well regulated in terms of voltage, a faulty port or wall/car adapter could potentially output 12V or more. Charging ICs are required to tolerate such over-voltage conditions, thereby protecting the downstream circuitry and eliminating damage to the portable equipment. Another important safety feature is battery temperature monitoring. If the temperature in a battery pack gets too hot, whether it is due to overcharging or high ambient temperatures, it can become a very serious safety hazard. In such cases, modern battery charging ICs can adjust charging voltage or current levels, and in extreme conditions even suspend charging to ensure battery and system health. Faster charging is another key requirement for modern medical devices, since it allows quick deployment for critical and timely patient monitoring. This is another benefit of the switch-mode battery charging architecture, particularly when powered by a current limited supply like a USB port. For a switch-mode battery charger, charging from an input current limited source, the following equation gives the current that is "multiplied" to charge the battery, due to efficient input-to-output power transfer in stepping down the voltage. Assuming an efficiency of 90%, an input voltage of 5V, an input limited source capable of 500mA, and a battery voltage of 3V, the current that will go to charging the battery will be 750mA.

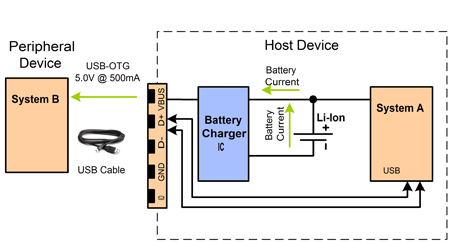

Another major driving factor behind the development of new portable medical devices is the need for user-friendliness. Given that the devices are targeting a highly diverse population in terms of age, education, ethnicity etc., handling and controlling the device needs to be straight-forward. The easiest interface, and the most universally known and recognized is the USB one. The great benefit of USB for a consumer is its familiarity; it can plug into most PCs or wall adapters, and charge their device, while synchronizing or downloading data. The problem then arises for the device manufacturer, who must ensure that the product is robust and interoperable with a high number of USB hosts, hubs, and wall adapters that may vary in quality. While the USB Battery Charging 1.1 specification has tried to standardize charging from a physical USB cable or connector, there are bound to be non-compliant devices that need to be accounted for. Examples may include adapters that are not properly rated in terms of output current drive capability. Clearly if an adapter that can supply 700mA is expected, but the actual adapter can only supply 300mA, then there will be problems with the battery charging resulting in the inability of a patient to charge the device for use. An ideal battery charger should then be able to charge a battery in accordance with the USB Battery Charging 1.1 specification, but should also have the versatility and flexibility to deal with non-compliant peripherals. Two additional benefits of the adoption of USB as the de-facto interface are: a) the wide industry adoption of micro USB connectors and cables, which guarantees a low-cost solution, and b) the enabling of USB On-the-Go. The later allows peripheral and master medical devices to connect, communicate with each other and share data without the need of a personal computer. Such an implementation is shown in the below figure.

Environmental trends also have a large impact on new medical electronic designs. The ownership of the equipment requires manufacturers to be responsible for battery replacement and recycling. The transition to rechargeable battery technologies, such as Li-Ion and Li-Polymer, addresses this issue and eliminates prohibitive cost measures (collecting and recycling old batteries) that may also be shared by patients and the healthcare industry as a whole. These batteries are also manufactured with materials that are environmentally friendlier than their older counterparts. Summary With an aging patient population and tremendous pressure for cost reductions in the healthcare market, enabling remote medical diagnosis and treatment as well as real-time retrieval of patient data is inevitable. While taking advantage of the popularity, features and environmental friendliness of Lithium-ion battery cells, medical device and equipment makers today must also rely on innovative technology to deliver the most effective charging and power management solutions to meet the market's stringent requirements. www.summitmicro.com/home/