Author:

Helmut Doenges, Marketing Director, Magnetec

Date

09/22/2011

Energy efficiency with advanced magnetic alloys - the quality of smart grids starts with the quality of their materials The famous English social reformer John Ruskin (1849 - 1900) was already well aware that a bargain-hunter mentality was the road to ruin. "There is hardly anything in the world that some man cannot make a little worse and sell a little cheaper, and the people who consider price only are this man's lawful prey." Today, however, the truisms that 'quality has its price' and 'a chain is only as strong as its weakest link' need to be re-established in many areas of modern life. One such area is energy supply. In the days of Ruskin, the scope of energy supply was confined to providing energy for general consumption in a technological form that was convenient to use and extremely straightforward to economically control. Our present age, however, is about to experience enormous change: in the near future, power supply systems will be compelled to metamorphose into 'smart grids', and buzzwords like 'energy efficiency', 'renewable energy' and 'energy management' will move into the limelight - generally focusing on grid operators and utility companies. In all of this, producers of passive components such as resistors, capacitors or inductors - the role of which should not be underestimated in the quality of the overall smart grid system - are largely ignored. Since both energy supply companies and manufacturers must apply an array of perspectives when considering the quality of generated energy and of all levels of the power supply, passive components - primarily soft magnetic components - are taking on growing significance in efficient power supply systems. Utility companies require increasingly precise information concerning the distribution grid, the method, scope, quality and sources of supply and the way in which different sources can be intelligently connected. The prerequisites for this vital information are not only the use of high-performance meters, but also the existence of efficient power supply systems. Smart grids and their components are thus facing enormous challenges, and we would do well to seek out the highest possible quality for all their elements, from power electronics components upwards, to ensure the smart grid of the future has a foundation of consistent efficiency at all levels.

The term 'sensing and measurement' is often used as a catch-all for important aspects such as grid stability, electromagnetic capability or energy theft prevention; however, it is rarely linked with the need for efficient devices in fields such as power electronics. High levels of precision in the information or identification of efficiency potential are only rarely called for, if at all. But the issue here is not only measurement precision; it also extends to minimum-loss generation of electric power. Furthermore, sustainable long-term development of efficient devices and systems can only be successful if developer and designer are familiar with the benefits of modern magnetic materials and aware of their wide-ranging potential applications. What the smart grid of the future must deliver - onwards and upwards, more and more And efficiency is the be-all and end-all: understandably given rising energy prices, calls for higher energy efficiency are growing louder. The goal is to make use of low-cost, or even cost-neutral components with minimum losses. However, a recurring problem in practice occurs when there is little or no knowledge of the right low-loss materials and when developers are often unfamiliar with the potential that can be harnessed by using the correct material to develop low-loss, grid-capable power supplies and converters - to name but two concrete examples. Expert knowledge of appropriate materials, the smallest building-block in the structure of a smart grid, is thus fast becoming a premium commodity. The smart grids of the future, with their labels of 'eco-friendly', 'high-performance' and 'highly flexible', must confront a vast array of challenges which can only be mastered by components that interact in the grid of the future and are designed for robustness and efficiency. Above all, smart grids must cope with the fact that power will no longer be sourced from a small number of central suppliers, but will come from a diverse range of decentralized sources - including consumers themselves, who generate power from solar plants, wind turbines or CHP plants and feed it into the grid, causing power fluctuations. These fluctuations are likely to increase as the numbers of feed-in sources and new forms of energy grow. In 2010, the proportion of renewable energy sources in the overall electricity balance rose year-on-year by almost ten per cent to 17 per cent, to give Germany as a concrete example. However, the inconsistency of the eco-power supply is a problem; wind is followed by calm, sunshine by clouds. And the challenges will only increase in the future. The German government has declared its minimum target of electricity from renewable sources as 80 per cent by 2050. Many countries throughout the world - particularly after the nuclear meltdown in Fukushima - are following suit. Changes will develop not only in the form of power that must be fed into the grid and transported, but also in its sheer volume: power from the increasing numbers of wind turbines, especially in Europe's coastal regions, will be joined by power from countless solar roof panels in southern climes, and the need for all this power to be transported represents an enormous new burden for the grid. Here too, there is no lack of examples of the significant role played by the correct highly efficient components; the power density of today's power supplies is increasing and the operating temperatures generated by solar inverters are rising, forcing the designers of devices to address the issue of managing thermal problems. The current load of active components in power electronics has continuously increased to the present day, even doubling in many cases. However, this gain is often offset by the underestimation of thermal problems in the selection of suitable passive components. Optimization of passive components is evidently moving up to join that of active components as a major priority. In addition to the thermal properties of passive components, the material used in them must assure adequate long-term stability. A lifespan of ten to twenty years is common for power supplies in smart grids; wind turbines, particularly offshore turbines for which maintenance procedures are difficult and complex, often have even stricter requirements. eMobility - the new consumer on the grid The grid of the future is also facing new challenges from the consumer side. The automotive industry is also advancing by leaps and bounds, embarking on the exploration of new trends. Concepts from hybrid drives to full electric-drive vehicles are currently in experimental phases - and herein lies the problem; the capacity of existing power distribution grids is far below that required for this additional power consumption by the electric vehicle sector. Future-oriented industries, particularly such as electric mobility, require the involvement of new centres of competence and stronger targeted collaboration that overarches technologies and industries. A few examples are new vehicle concepts, electric drive technologies, power electronics components, high-performance batteries and integration into the energy infrastructure, extending to the development of innovative mobility concepts. The development of chargers for electric vehicles, to give another concrete example, is primarily aimed at achieving high power density and efficiency exceeding 97 per cent. And once again we end up facing passive components: a specification of this magnitude can only be achieved through ultra-low conduction losses from new types of semiconductors and the simultaneous use of low-loss magnetic materials.

Still plenty to do Little time remains to upgrade today's power grids to smart grids in readiness for the challenges described. Rising raw materials prices, the imminent exhaustion of fossil fuels, the recently revived nuclear debate which has already led to concrete plans for nuclear phase-out and the accompanying growth of support for renewable energy sources are transforming new forms of energy management into a top-priority issue at many levels. In addition to the essential acceleration of the processes of grid conversion and upgrading, corresponding regulations and standards will soon be implemented to govern the extension and optimization of existing distribution grids and the introduction of efficient, high-precision monitoring. Monitoring involves the use of control instruments that enable grid operators to draw up, say, wind and solar forecasts as a basis for short-term addition of power station capacities. What is required is thus a meaningful interaction of hardware and software components, complemented by a blanket rollout of smart meters in an advanced metering infrastructure (AMI) for the launch of remote metering. This sector in particular will require high-precision and durable components for electricity metering which deliver reliable and stable measurements. Current transformers with soft magnetic cores are particularly suitable.

Highly industrialized countries such as Germany and Japan are now in the unique situation of being able to step into the role of technology leader in expanding and upgrading the power grids of the future. The majority of producers of advanced power electronics components that can guarantee stability and reliability - and thus the quality of the smart grid from the outset - are located in Germany and are ready to face these challenges. The aim must be to convince all those involved in creating the smart grids of today and tomorrow - such as, to take examples of components already mentioned, the manufacturers of inverters, those key 'translators' between power generators and grid, or of grid components - that they should use correct and suitable components from the outset in building their products, to eliminate later risks of unpleasant surprises from asymmetry and interference. It is actually the case that measures designed to increase the efficiency of on-grid inverters for solar plants or wind turbines are currently being prioritized by the relevant manufacturers. Every tenth of a percentage point is more than welcome in reducing losses or boosting efficiency. The issue is to replace widespread standard components with efficiency-optimized specialist solutions, especially where inductive components such as chokes in the essential EMC filters are concerned. Moving from the general to the specific, ferrite cores have to date been the most widely used standard components in common-mode chokes for EMC filters. Replacing them with higher-quality nanocrystalline tape-wound cores could increase permeability up to fivefold - while enabling more compact designs to be produced. The result is a dramatic fall in choke losses, typically of up to 50 per cent. And nanocrystalline material need not be more expensive than ferrite cores. Calculated in simple terms, the extra costs of purchasing these energy-efficient components can be recouped from the feed-in payments from a 3x25A/1.5mH common-mode choke after only a few months.

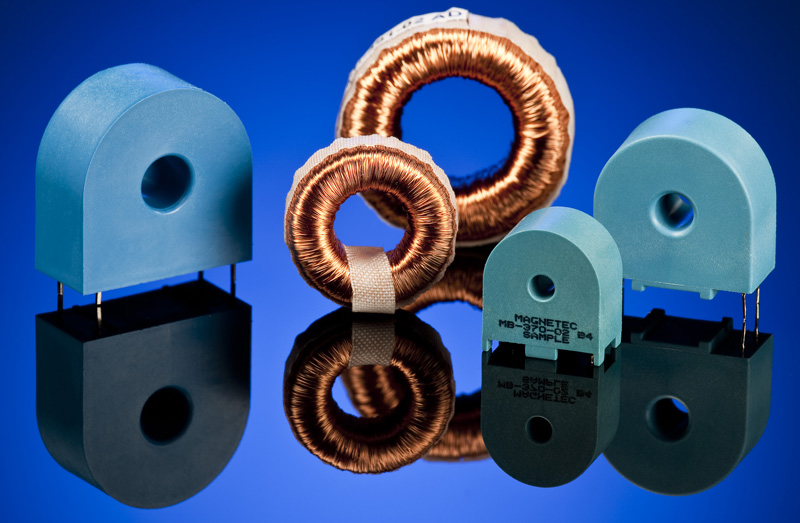

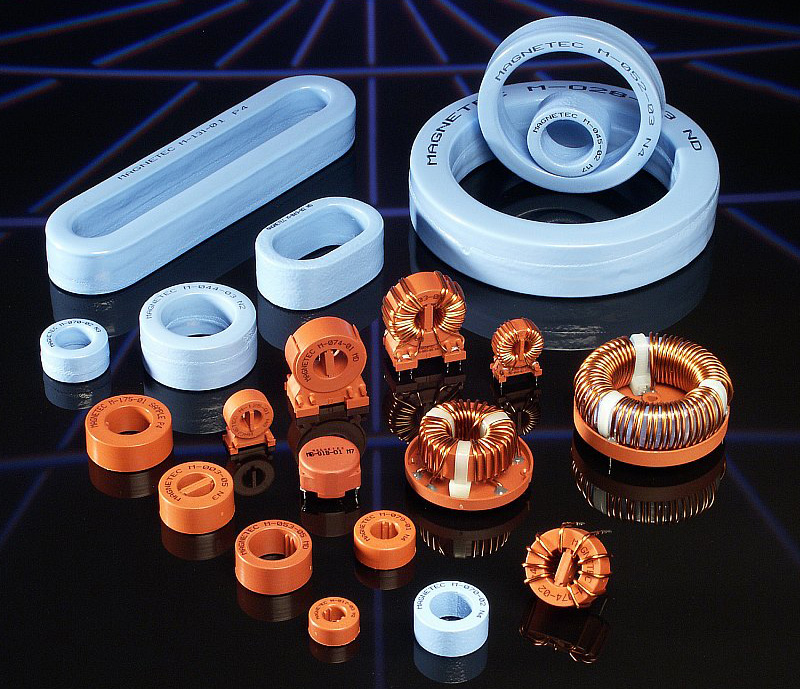

Nanocrystalline materials step up to the plate The raw materials shortages already noted are resulting in soaring prices for many basic metals used in soft magnetic alloys. However, nanomaterials - 90% of which are produced from the significantly cheaper raw materials, iron and silicon - are almost unaffected by this development. They can often represent a lower-cost alternative yet also offer technological benefits, as described in the example of the choke above. Trends in modern power electronics are moving towards higher frequencies and more compact designs or greater power density. As a result, recent years have seen an increase in the number of industrial power electronics applications using nanocrystalline cores, accompanied by a rise in demand which is slated to continue. A wide variety of cores, transformers and chokes are used in applications including the following, all of which are also found in smart grids: • Power electronics (EMC filters for inverters and all forms of pulsed power supply) • Installation technology (RCCBs; triggering transformers for protective relays or line protectors and electronic electricity meters) • Renewable energies (solar inverters and wind turbines) • Stationary and mobile charging devices for electric vehicles The soft magnetic nanocrystalline alloy FeCuNbSiB has been available for some years under brand names such as NANOPERM®, FINEMET® and VITROPERM®. A relatively simple yet revolutionary production method is used to produce ultra-thin strips from low-cost materials such as silicon and iron. The result is a new generation of materials offering a unique combination of outstanding soft magnetic properties. For the first time, a single material offers roughly the same high induction swing as silicon iron ('transformer blanks') together with better high-frequency characteristics than those of ferrite (low loss, high permeability). This nanocrystalline alloy also offers a significantly more competitive price-performance ratio than the amorphous co-alloys that broke new ground at the end of the 1980s, with comparable or even superior characteristics. Today amorphous co-alloys are generally used only rarely in special applications owing to their high cost and environmental impact. Present and future areas of application As briefly mentioned previously, a primary area of application for the new material is in the manufacture of common-mode chokes for EMC filters, used in all types of pulsed power supply including variable speed drives (frequency converters). In this area it offers significant benefits in volume, since both its relevant material properties (permeability and saturation inductance) are significantly higher than those of ferrite, otherwise the traditional choice for these applications. The new Cool-Blue® cores serving as protection from harmful motor bearing currents are also growing in popularity, particularly in inverter systems with high and highest outputs such as wind turbines with 1 - 3 MW or printing and paper industry plants.

Further major applications already realized include power transformers for switched-mode power supplies with an output range from several hundred watts to several hundred kW, current limitation cores, magnetic amplifier chokes, drive transformers for IGBT transistors, mains-independent RCCBs, current sensors and current transformers for the new electronic electricity meters. More will follow - particularly in connection with the continuously advancing field of switching topologies or new systems currently under development in the automotive industry. High-tech manufacturing processes The manufacturing process uses rapid solidification technology. A charge of liquid metal weighing 50-200 kg with a temperature of approximately 1,300°C is poured through a specially shaped ceramic nozzle directly onto a rapidly rotating water-cooled copper casting wheel, where it solidifies within a thousandth of a second. As this happens, a continuous metal strip, initially amorphous and only 20 mm thick, is extruded from the liquid metal at speeds of over 100 km/h. In other words, this product is manufactured in a single process step involving a relatively compact production facility, eliminating the need for costly cold or hot rolling plants. The tape-wound cores produced from the metal strip are then annealed under inert gas within magnetic fields in longitudinal or lateral orientation to the tape direction. Under this irreversible heat treatment, the originally amorphous structure of the material finally forms microscopic crystallites with typical grain size of 10 nm - hence the name 'nanocrystalline'. When precise control is applied to the parameters of heat treatment (temperature, time, rate of heating or cooling), the required properties of the material (e.g. form of hysteresis loop or permeability level) can be extensively varied and precisely set. MAGNETEC is one producer of these nanocrystalline elements, such as filter chokes for power supplies and power electronics inverters. By using extremely compact EMC chokes with tape-wound NANOPERM® cores, MAGNETEC is able to significantly improve EMI filtering in e.g. solar inverters and frequency converters in drive technology. MAGNETEC filters have been the technologically state-of-the-art choice for many years - particularly for extremely small designs requiring maximum attenuation. Conclusion This short excursion into the world of nanocrystalline materials clearly reveals the potential still to be exploited in the area. Smart grid assemblies constructed of components as described here which have, so to speak, a hidden impact, play a significant role in completing the intelligent power grid of the future in compliance with the host of requirements posed by current and future developments, and thus in ensuring reliable, stable energy management. False economies would be absolutely fatal in a project on this mammoth scale, which could have unforeseen impacts on our lives in the future. As Seneca (Lucius Annaeus Seneca, approx. 4 BC - 65 AD, Roman politician, master of rhetoric, philosopher and writer) already warned, "It is quality rather than quantity that matters". He was right - and so was John Ruskin. www.magnetec.de