Author:

Scott Ludwig, Progea USA

Date

10/11/2013

In addition to photovoltaic systems to produce solar energy, another technology exists that can make better use of clean energy based on the principle known as thermodynamic solar power. Opened in October 2011, Gemasolar established the first commercial-scale solar power plant in Andalusia, in the region of Seville in Spain. This plant is capable of supplying electricity for 25,000 homes 24 hours a day by solar heating molten salt to over 500 °C. The Gemasolar facility extends over a surface area equaling the size of 260 football fields, and is located along the motorway, which links Seville with Cordoba. The power plant's technical director, engineer Santiago Arias, stipulates that this photovoltaic power plant is the only one of its kind in the world that carries on working even when the sun has set. The photovoltaic panels used in the power plant are not those that convert sun light into electric energy but concentrate and use the sun's thermal energy. The plant's structure consists of a forest of gigantic panels positioned around a big tower in the center. About 2, 650 mirrors reflect the sun's rays towards the top of the tower (see Figure 1). To maximize the concentration of solar energy, each one of the 110 square meter heliostats (mirrors) automatically follows the sun's movement from dawn to dusk in the same way sunflowers do. In the top of the tower, with thousands of rays focused on it, the molten salt used (which is a mixture of 60% potassium nitrate and 40% sodium nitrate) is heated to 565 °C. Inside a heat exchanger water is circulated in the manner of nuclear power plants, with the intense heat of the salt producing steam to spin the turbines connected to the electric generator. The sun heats the tower until sunset, but this does not impede Gemasolar in keeping the turbines running for another 15 hours. The concentrated energy from the mirrors should in theory be able to heat the salt to even higher temperatures, but in order to withstand such extreme boiling temperatures a more robust and expensive structure would be needed. The actual structure alone amounts to 250 million euro in investments. Torresol, the company that established and manages this company, is 60% owned by Sener Grupo de Ingeneri?a S.A. a Spanish engineering company. The remaining 40% shares are in the hands of Masdar, from the emirates of Abu Dhabi, who invest heavily in renewable energy. Gemasolar is capable of producing 400 MWh a day while running continuously at 20 megawatts. This is four times more than the facility planned for construction in Curbans in the Provence region of France, which has been designed to alternate between day and night and is sensitive to cloudy weather.

The Solar Thermal Power plant structure This center features rings of mirrors in an array measuring 10 x 10 meters that reflect solar radiation onto a receptor on top of the tower in the center. The receptor exchanges energy with the molten nitrate salt flowing through the tower. The salt is driven from a ‘cold tank' to the receptor located at the top of a 140-meter-high tower where they are heated to 565°C. (see Figure 2) The heated molten salt then descends to the heat exchanger to produce steam. When sufficient solar radiation heat has been received to create energy for power driving the turbines, the surplus salt is then deposited in a storage hot tank by the system. This heat produced by the salt is therefore stored and used when the solar radiation level is low so that electricity can still be produced when there is no sun. When needed the salt then transfers the stored heat and continues to produce electric ?energy. The stored molt salt can continue providing electric energy up to seven hours without solar radiation. Solar: Photovoltaic or Thermal Power? The thermo-electricity is therefore a particular type of renewable energy that exploits sun radiation. There are some fundamental differences between solar thermoelectric power technology and Photovoltaic technology: whereas photovoltaic technology converts solar radiation directly into electric energy, without generating and using the movement of mechanical parts, the solar thermoelectric power technology uses the thermal energy of the sun to heat a liquid to produce high pressure steam. ?Another difference in thermoelectric is that unlike photovoltaic technology that can also work in cloudy weather conditions with filtered solar radiation, the solar thermoelectric needs constant and direct sun radiation. Therefore there are two essential aspects to enable relatively efficient energy production using this technique: first of all and most apparent, solar thermoelectric plants need to be built in semi-arid areas to ensure that they are fully and constantly exposed to the sun. Secondly, it is very important how the fluid is exposed so that it does not disperse heat easily: for this reason a specialized fluid has been developed to maintain its boiling hot temperature once heated to over 500 degrees for several days, without contact with the energy source. This system can enable around 95% exploitation of the solar spectrum and represents a new frontier in the search for alternative energy. To guarantee that the system works correctly and to improve its efficiency, an innovative technology has been set up and deployed by Infraservice Srl, which uses thermographic detection by managing data in a supervision and control system based on the Movicon 11 Scada technology. Infraservice S.r.l is a young and dynamic company operating in the thermography applied to industrial automation sector. To begin, Infraservice has engineered the use of a Scada system with a thermo camera obtaining optimum results and positive response from the market within which the company operates such as pharmaceutical, chemical, cement and die manufacturing with the assistance of the technical support which comes with the Progea products. The innovative approach used in applications has gained optimum results in industrial automation by offering solutions based on captivating and modern graphics with userfriendly interfaces that are greatly appreciated by clients for their simplicity-of-use. The system designed for Gemasolar is composed of 4 thermocameras (640 x 480 pixels) mounted on poles in the four cardinal points. These thermocameras are connected with each other in fiber optic gigabit ethernet. The thermographic images are collected and processed at a frequency of around 30 Fps (frame per second) in real-time by the Movicon Scada Software residing in the control room and connected to the thermocameras using the Ethernet network.

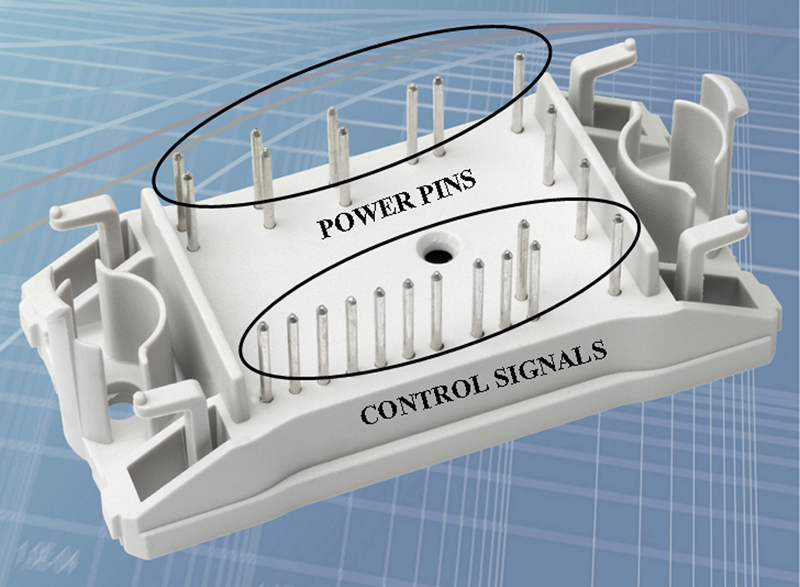

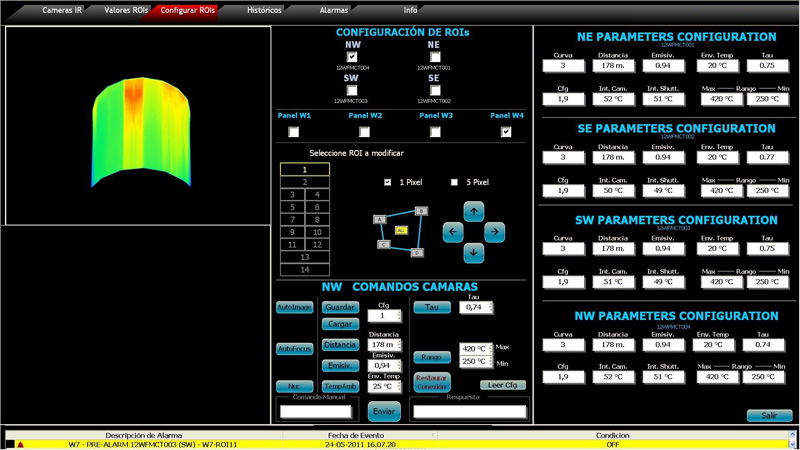

Thermal data acquisition By means of analyzing the thermographical images, retrieved from the thermographic cameras, the application created with Movicon, transfers the information concerning the temperatures of all the receptor surfaces highlighting eventual thermal anomalies that might cause serious damage to the structure. The retrieved information on temperatures is sent to a PLC, which relays it to the mirror control system. This system then regulates the inclination of each mirror to correctly radiate homogeneous temperature to the receptors placed on the central tower. Movicon in the energy sector Supervision, monitoring and control with Movicon 11 includes alarm management for retrieving temperature data in realtime while displaying trends on recorded temperatures with the ability to set a series of settings and commands to transmit to the four thermocameras. Each thermocamera has been configured using the 56 ROI thermographic software (Region of interest) with which the Maximum, Minimum and Average temperatures are measured in realtime for each camera. These values (672 temperature values altogether) are processed by a datalogger and displayed in the Trend Historical screen pages. In addition this data is sent to the PLC using the TCP-IP Modbus communication. This supervision application also manages alarms on the retrieved temperatures, displays Trends on recorded temperatures and provides the ability to set a series of settings and commands to transmit to the 4 thermocameras (see Figure 3). Leading the industry by installing solar thermal power with 432 MW in early 2010 in Spain, the company has recently setup operation in the U.S.A by installing the equivalent to 422MW in solar thermal power at the beginning of this year. Conclusion It can be reaffirmed that the solar thermal power technology developed by Professor Rubbia, offers great advantages in the field of energy production from ecologically sustainable and renewable sources. The supervision and control technology implemented by Infraservice exploits the capacity to retrieve thermal data to ensure system efficiency and safety, simplifying the automation system and application of field components. Movicon has not only proved particularly effective for this application but also for other types of thermographic detection applications in various industries. Progea