Author:

Claudio Spini, Senior Engineer, Application Laboratory, STMicroelectronics, Italy; Davide Giavarini, EPCOS AG (Group Company of TDK-EPC), IC Reference Design, Italy; Wolfgang Dreipelcher, EPCOS AG, Senior Director IC Reference Design, Germany

Date

05/01/2010

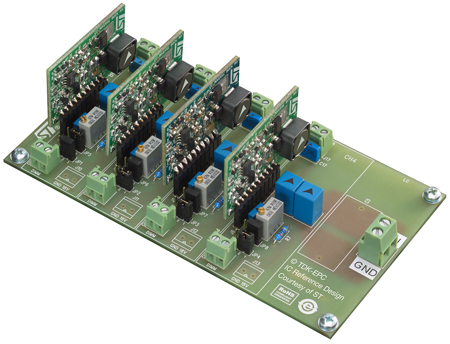

For an advanced PCB-design, developers want to make the right choice by knowing thoroughly the application and specific requirements. Next to the design assistance this is the most important reason for App-Notes issued by the IC makers. In this early stage, IC makers such as ST need the support of a broad liner in passive components like TDK-EPC. The wide portfolio of TDK-EPC, allows the choice of the right components out of this portfolio. As a result of features such as high efficiency and very long lifetime, LEDs are becoming increasingly popular. They are driving innovation of current lamp types and make a substantial contribution to energy reduction for internal or external lighting. This is also happening in street lighting applications, where the higher efficiency and lifetime are vital for reducing total costs (including maintenance) and energy consumption. For these reasons, a street lighting power supply designed to power an LED lamp has to have high efficiency and at least similar lifetime to the LED, in order to guarantee the maintenance-free operation required by this kind of application during the LED's useful lifetime. This article describes the characteristics and features of a 130W reference design board adapted to a LED power supply specifically designed for street lighting. The circuit is composed of two stages: a front-end PFC using ST's L6562AT and an LLC resonant converter based on ST's L6599AT. The main features of this design are very high efficiency (more than 90%), a wide input mains range (85-305 VAC) operation and long term reliability. Because reliability (MTBF - mean time between failures) in power supplies is typically affected by electrolytic capacitors and their high failure rate, unless very expensive types are used, this board shows an extremely innovative design approach. This board uses film capacitors from Epcos instead of electrolytic capacitors. Component derating has also been carefully applied during the design phase, so decreasing the component stress as recommended by MIL-HDBK-217D. With the use of ST's new L6562AT and L6599AT devices, the number of components used for this solution has also been minimized, thus increasing the MTBF and optimizing the total component cost. As a result of the high efficiency achieved, only a small heatsink for the PFC stage is needed, while the other power components are SMT like most passive components, thus decreasing the production labour cost. The board is also protected against overload or short circuit, open loop of each stage or input overvoltage because of the particular application, after intervention the system auto-restarts.

The PFC stage, working in transition mode, acts as pre-regulator and powers the resonant stage with the output voltage of 450V. The PFC power stage is a conventional boost converter, connected to the output of the rectifier bridge. It is completed by the boost coil, the rectifier diode and the output capacitors. The PFC output capacitors are film type, 5?F, 800V from Epcos. The boost switch uses a MOSFET. The board is equipped with an input EMI filter required to filter the commutation noise coming from the boost stage. The PFC implements the controller L6562AT, a small and inexpensive controller guaranteed for operation over a wide temperature range necessary for outdoor operation.

The downstream converter implements the ST L6599AT, incorporating all the functions necessary to correctly control the resonant converter and working with 50 percent fixed duty cycle and variable frequency. The transformer uses the integrated magnetic approach, incorporating the resonant series inductance. Thus, no additional external coil is needed for the resonance. The transformer configuration chosen for the secondary winding is the typical center tap, using a couple of power Schottky rectifiers, type STPS10150CG. The output capacitors are film type, 4.7?F, 63V from Epcos. A small LC filter completes the output section in order to filter the high frequency ripple. A feedback network guarantees the required stability of the output voltage.

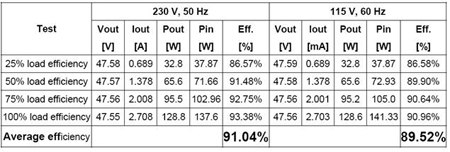

Table 1 shows the overall efficiency, measured at 230Vac, 50Hz and 115V, 60Hz with different loads also. At 115Vac and full load, the overall efficiency is 90.96% and it increases up to 93.39% at 230Vac. This makes this design suitable for applications requiring high efficiency. Measuring the efficiency at 25%, 50%, 75% and 100% according to the ES-2 standard and calculating the average efficiency, this is 91.04% at 230Vac and 89.52% at 115Vac. This shows that the converter can operate with a high efficiency not only at full load but also at lower loads such as in the case of LED deep dimming.

A 48V to 130W power supply for street lighting applications has been designed and the prototype has been tested. The adopted solutions meet the LED street-lighting specifications for wide input voltage range, wide temperature range operation and high efficiency. Additionally, the design guidelines and solution implemented meet the required MTBF target. www.st.com www.epcos.com