Author:

Reported by Cliff Keys, Editorial Director, Editor-in-Chief, Power Systems Design

Date

11/30/2010

Nextreme Thermal Solutions offers electronics cooling and energy harvesting solutions for telecommunications, semiconductor, consumer, medical, aerospace and government markets. The company uses microscale thermoelectric technology and high-volume semiconductor manufacturing processes to address the growing needs for advanced thermal management and clean-energy solutions world-wide. Nextreme also offers sophisticated modeling, design, engineering, and contract manufacturing services to deliver fully-optimized solutions from standard and customized products that solve the most challenging thermal and power management issues. Nextreme Thermal Solutions, announced that it has been awarded a United States patent for the design of an innovative solar thermoelectric generator (solar TEG) for high-temperature solar thermoelectric energy conversion. Patent #7,638,705 - Thermoelectric Generators for Solar Conversion and Related Systems and Methods describes a method of using thermoelectric generators in combination with thermally conductive plates to generate power in response to solar radiation. Thermoelectric devices generate electricity via the Seebeck Effect, where voltage is produced from a temperature differential applied across the device. High-temperature solar thermal systems that incorporate solar concentrators can operate between 600° and 700°C. At those temperatures, a multi-stage cascade thermoelectric power generator, as depicted in the above illustration, may provide a design efficiency of well over 15%. Design efficiencies in this range permit flexibility and adaptability to new and cost-effective real-world solar thermal systems. "One of our missions is to harness new sources of energy using disruptive thermoelectric materials and device technology," said Jim Mundell, chief operating officer at Nextreme. "This solar TEG patent demonstrates our continued leadership in developing new solutions for clean energy harvesting." The invention was developed in collaboration with Dr. Rama Venkatasubramanian, director of the Center for Solid State Energetics at RTI International in Research Triangle Park, North Carolina.

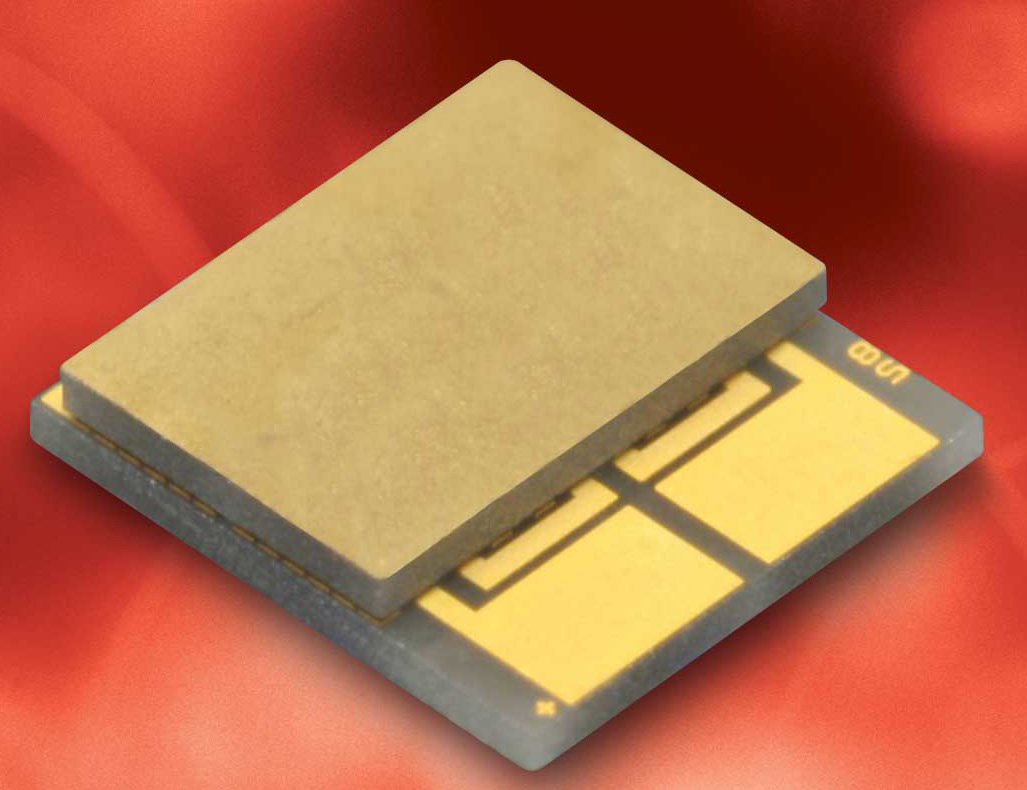

New eTEG HV56 Thermoelectric Power Generator Cranks-up the Juice Nextreme announced the availability of the new eTEG™ HV56 thermoelectric power generator, the next entry in the high-voltage (HV) series of clean energy generators based on thin-film thermoelectrics, that operates at temperature differentials as low at 10K. When combined with batteries and energy cells, the HV56 offers an ideal steady-state energy solution for a variety of self-powered applications in the wireless sensor, automotive, aerospace, industrial and medical device markets. The HV56 is capable of producing 1.5mW of output power and an open circuit voltage of 0.25V at a 10K ?T in a footprint of only 11mm2. At 50K ?T, the HV56 produces 36.5mW of power and an open circuit voltage of 1.25V. The module is extremely thin: only 0.6mm high, and can be configured electrically in series to produce higher voltage and power outputs. The use of thermoelectric power generators (TEGs), in which a temperature difference creates an electrical potential, can convert waste heat from thermal sources into electricity for an alternative source of energy. In reality, most heat sources come and go and the actual temperature difference depends on several factors such as the time of day, wind speed and heat output, among other variables. Trickle charging energy storage devices using an HV56 power generator offers an ideal solution to provide steady-state energy from variable heat sources. "For trickle-charging applications using thermoelectrics, a power convertor is required to meet the minimum charge voltage of the cell, such as 3.3 volts for lithium ion batteries," said Dave Koester, vice president of engineering at Nextreme. "Our new HV56 power generator, in conjunction with the latest advances in voltage up-conversion, enables our customers to get the voltages they need at very low ?Ts." The high voltage output of the HV56 is enabled by Nextreme's proprietary micro-scale thermoelectric technology. Certain applications (e.g., generating power off the heat of the human body, or generating power for wireless sensors) require a high density of thermoelectric elements in order to generate power at low temperature differentials. Nextreme's patented thermal bump fabrication process can achieve thousands of elements per square centimeter. Nextreme engineers are currently working with customers in a variety of industries and applications. These include clean energy harvesting and storage solutions for wireless sensor networks and remote power management. The eTEG HV56 is RoHS-compliant and manufactured using eutectic gold-tin (AuSn) solder, which enables assembly temperatures as high as 320°C. The module is available with an 8 to 10 week delivery lead time. Pricing is available upon request. Nextreme recommends the use of its thermal modeling, design and engineering services to deliver fully-optimized energy harvesting solutions. Nextreme routinely conducts analytical and numerical thermal modeling at all design levels from component to module to subsystem. Advanced analysis of complex systems, components or packages often require more detailed modeling to understand heat flow and thermal gradients.

Nextreme Scales-up with New eTEC Hv56 Electronics Cooler Nextreme introduced the eTEC™ HV56 module, the next product in its high-voltage (HV) line of thin-film thermoelectric coolers (TECs) designed to address electronics cooling applications with larger heat pumping requirements. At 85°C, the eTEC HV56 can pump 6 watts or 58 W/cm2 of heat in footprint of only 11 mm2. The device is only 0.6mm high, At 85°C, the eTEC HV56 can create a temperature differential (?T) of up to 60°C between its hot and cold sides, and operates at a maximum voltage of 10.8V, making it compatible with commonly found board-level currents and voltages. At 25°C, the device can create a ?T of up to 50°C with a maximum voltage of 8.8V. The eTEC HV56 is RoHS-compliant and is manufactured using gold-tin (AuSn) solder, which enables assembly temperatures as high as 320°C. These assembly temperatures make the HV56 compatible with industry standard processes for packaging electronic devices that require tight tolerances. "Many of our customers have been asking for a higher wattage device in a single package," said Dave Koester, vice president of engineering at Nextreme. "The eTEC HV56 has four times the heat pumping capacity of our HV14 module and operates at higher voltages, making it easier to drive. The introduction of the HV56 also demonstrates our ability to scale up our technology in a variety of configurations based on customer requirements." Nextreme engineers are currently working with customers in a variety of industries and applications. These include laser diode cooling, high-speed thermal test heads, and CPU hot spot cooling. The eTEC HV56 module is available with an 8 to 10 week delivery lead time. Pricing is available upon request. Nextreme recommends the use of its thermal modeling, design and engineering services to deliver fully-optimized thermal management solutions. Nextreme routinely conducts analytical and numerical thermal modeling at all design levels from component to module to subsystem. Advanced analysis of complex systems, components or packages often requires more detailed modeling to understand heat flow and thermal gradients. For more information, visit www.nextreme.com, or in Europe www.nextreme.eu