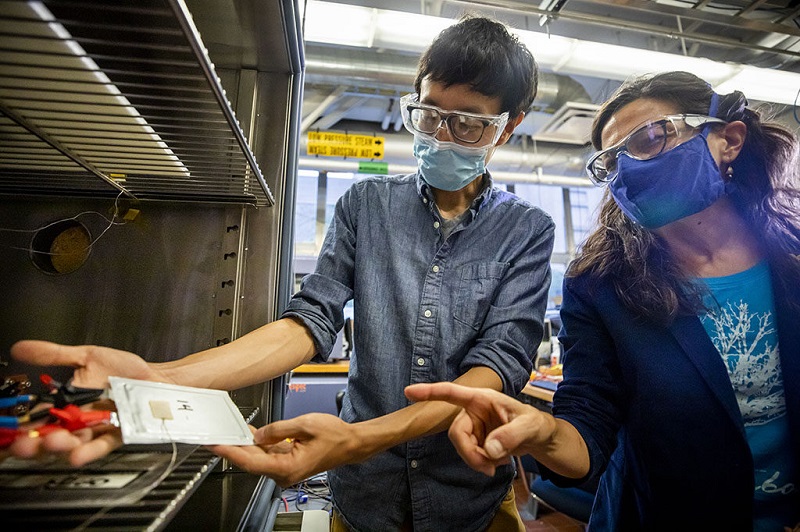

Andrew Weng, a PhD student in mechanical engineering, and Anna Stefanopoulou, the William Clay Ford Professor of Technology, identify an early-life diagnostic signal that predicts the impact of the formation protocols on battery life without needing cycle life testing.

Batteries are becoming more and more important to our lives, and that need will only grow as electric vehicles continue to take over from internal combustion engine powered automobiles. To try keep up with demand, manufacturers are trying to produce as many batteries as possible while keeping costs low, and that means trying to quicken the formation of the battery as much as they can. However, if that formation of the battery is too fast, it can have a detrimental effect on its usable lifetime. Until now, the only way to find out the lifetime of a battery was to repeatedly charge and discharge to battery to provide the data required for the algorithm to work out the calculation. These ageing tests can take some time, and due to that, it is usually only possible to test some of the produced cells.

Now, a team of researchers from the University of Michigan have developed a simple and cheap test that can be performed on all batteries to provide the data needed for calculations. The test measures the cell resistance at a low charge state. The result correlates to the cycle life and is used to improve the accuracy of data-driven battery lifetime prediction models. The signal is taken at the end of the manufacturing line, only takes a few seconds to acquire, and does not add any additional capital cost. The research also looks at the physical connection between that resistance signal and the amount of lithium consumed during formation. This connection suggests that the test may be broadly applicable for evaluating any battery manufacturing process or design change that could impact the total lithium consumed during formation.

The new test is an indication of how much lithium has merged with the liquid electrolyte. The combination layer, known as the solid electrolyte interphase, can protect the surface of the electrode and enable longer lifetimes. How much lithium is in the solid electrolyte interphase is usually difficult to measure. However, at low charge, the battery's internal resistance is closely related to how much lithium went into the solid electrolyte interphase - providing a quick measure of that protective layer, as well as the operating capacity of the battery.

The research was funded by the National Science Foundation. The team ran experiments in the U-M Battery Laboratory. A collaborator at Stanford University contributed to the analysis.