Author:

Maurice O' Brien, Product Marketing Manager, Power Management Division, Analog Devices

Date

05/17/2013

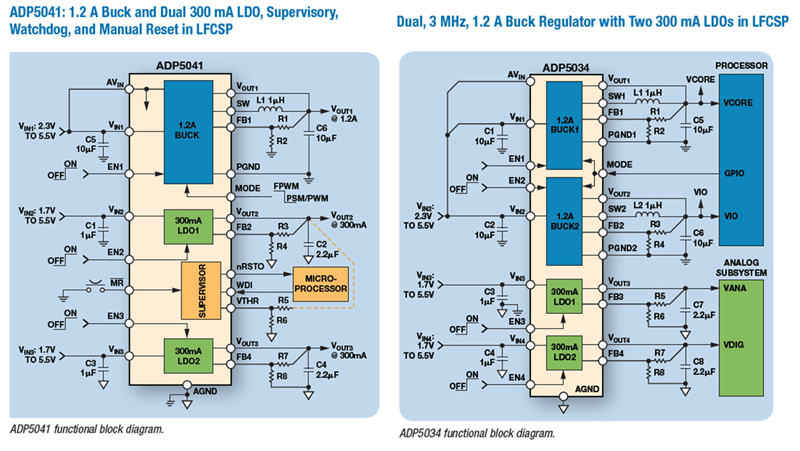

As the form factor of machine vision systems continues to get smaller while the processing power in these systems continues to increase rapidly. Power management is becoming a more important design aspect for new machines vision systems. The latest FPGAs and processors used in machine vision systems today have a common requirements of needed multiple rails to power them. Traditionally the power supply for these FPGAs and processors required multiple discrete switching regulators and LDOs. In these discrete power designs the switching regulators where used to power the high current core rails and the LDOs used to power the more nose sensitive, lower current clocking rails. New more integrated power management solutions are being developed to meet the smaller PCB area requirements such as in machine vision systems. These new multi-channel integrated power management solutions that integrate multiple switching regulators, LDOs and supervisory/watching timers into a single chip IC, significantly reduce the solution size, cost and design time of typical multi rail power supply for an FPGAs. As customers design cycles continue to shorten it is becoming more important to have a single power IC that generates multiple rails that are very flexible and easy to configure so that this one multi-channel IC, can be used in different applications/configuration quickly and easily reducing design time and reducing time to market for new products. (See Figure 1.) The Advantages of using uPMUs to power FPGAs and Processors include: • Cost effective solution • Small board footprint • Can simplify sequencing and voltage tracking • Low Noise, switchers out-of-phase operation, reduces EMI • No need for external synchronization signal • Easy to use, does not need much power expertise • Less components and improved reliability Let's look at four of these key advantages in detail: Solution Size By integrating multiple switching buck regulators, LDOs, supervisory and watchdog functionality in to a single chip solution, the PCB area of a multi-rail power supply solution can be significantly decreased. The ADP5034 is a dual 1.2A buck regulator with two 300-mA LDOs in a 24-LFCSP package and provides a good example case. The ADP5034 enables a new generation of highly integrated multi-output regulators that require very little board space by integrating multiple switching regulators and LDOs in a single package. The integrated switching regulators operate at 3MHz switching frequency allowing very small chip inductors to be used, significantly reducing the total solution size. The ADP5034 total solution size is only 72mm square. Ease of Use As the design cycle of new products continue to decrease, the need for new power management solutions that are easy to design initially but also easy to modify for future design requirements is becoming more important to meet new product release dates. The ADP5041 multi-output regulator provides a 1.2A buck regulator with two 300mA LDOs along with an integrated power on reset and watchdog timer for high reliability processor based systems. All the ADP5041 integrated regulators have dedicated enable pins to allow maximum flexibility for the power supply designer to enable/disable each of the three regulators in hardware without any software overhead, enabling easy power supply sequencing for the three rails. The output voltage of each of the three regulators is set using an external resistor divider again allowing the power supply designer to quickly and easily change the output voltages during prototyping and for new design re-use requiring a different combination of output voltages. The combination of individual enable pins with resistor programmable output voltages on each integrated regulator of a multi-output regulator significantly help power supply designs reduce the design complexity and design time help to get new products to market sooner.

Less Components and Improved Manufacturing Reliability Figure 2 shows an example layout of a discrete dual 1.2A buck regulator and dual 300mA LDO power solutions against the single chip ADP5034 multi-output regulator. The discrete power solution requires 22 components to be placed on 97mm2 PCB area compared to the ADP5034 solution of 19 components to be placed on 72mm2 PCB area. The ADP5034 solution requires 35% PCB area and saves the cost of placing 3 components, the cost of placing a component on a PCB can be as high as three cents, when the cost of purchasing, inventory, placement, inspection are considered. The more components that you have to place on a PCB the higher the risk of manufacturing defects, by reducing the number of components to be placed on a PCB the cost of manufacture is reduced but the reliability of the manufacturing process is increased. Low Noise Solutions A dedicated MODE pin on the switching buck regulators can be conveniently controlled by a microprocessor GPIO port forcing the switching regulators to operate in constant PWM mode, this can be necessary when the supplied circuit (Transceiver, ADC, Audio) is sensitive to wide band noise due to the burst operation of a switcher when operating in light load condition. The LDOs integrated into these multi-output regulators have an input voltage range of 1.7 V to 5.5 V, the low input voltage range of the LDOs allows them provide a very high efficiency low noise output by combing one of the buck regulators with an LDO. For example the buck regulators can be used as pre-regulators to give a high efficiency drop from a 5V input to 1.8V output on the buck regulator, this 1.8V is then applied to the input of the LDO to provide a very low noise 1.2V output voltage for powering very sensitive analog circuitry with very high power efficiency from the initial 5V input. The integrated LDOs have high PSRR, even with a low Vin-Vout headroom, and low inherent noise, in addition crosstalk between regulators has been minimized. All these characteristics are important when supplying noise sensitive circuits. Analog Devices