Author:

Jeff Gruetter, Product Marketing Engineer, Linear Technology

Date

05/01/2010

In 2010, the market size for high brightness LEDs is expected to reach $8.2 billion and grow to $20.2 billion by 2015 at a 30.6% compound annual growth rate (CAGR) according to Strategies Unlimited. LEDs used to backlight displays are currently the major driver to this growth. Applications range from HDTVs to automotive displays to a myriad of handheld devices. In order to maintain this impressive growth rate, LEDs must not only offer enhanced reliability, reduced power consumption and smaller/flatter form factors, but must also offer obvious improvements in contrast ratios, picture clarity and color accuracy. Additionally, automotive, avionic and marine displays must maximize all of these improvements while subjected to a wide array of ambient lighting conditions, ranging from bright sunlight to night-time environments. These transistor-liquid crystal display (TFT-LCD) applications range from infotainment systems, gauge clusters and a wide array of instruments. Backlighting these displays with LEDs creates some unique LED IC driver design challenges in order to optimize the displays' readability in such a wide range of ambient lighting conditions. This requires LED drivers that can offer very wide dimming ratios, high efficiency and withstand the rigors of the relatively caustic automotive electrical and physical environment. Finally, these solutions must offer very low profile, compact footprints while enhancing cost effectiveness. How can such an impressive growth potential in automotive lighting be supported? First of all, LEDs are ten times more efficient at producing light than incandescent bulbs and almost twice as efficient as fluorescent lamps, including cold cathode fluorescent lamps (CCFL) thus reducing the amount of electrical power required to deliver a given amount of light output (measured in lumens), as well as the dissipated heat. As LEDs are further developed, their efficiency at producing lumens from electrical power will only continue to increase. Secondly, in a very environmentally conscience world, LED lighting does not require the handling, exposure and disposal of the toxic mercury vapor commonly found in CCFL/fluorescent bulbs. Thirdly, incandescent bulbs need to be replaced about every 1,000 hours, while fluorescent bulbs last up to 10,000 hours compared to a 100,000+ hour lifetime for LEDs. In most applications, this allows the LEDs to be permanently embedded into the final application without the need for a fixture. This is especially important for backlighting automotive instrument/navigation/infotainment panels that are embedded into a car's interior as they will never require replacement during the life of the car. Additionally, LEDs are orders of magnitude smaller and flatter then their counterparts so the LCD panels can be very thin, thereby requiring minimal space in the interior of the car. Furthermore, by using a configuration of Red, Green & Blue LEDs, an infinite number of colors can be delivered. LEDs also have the ability to dim and turn on/off much faster than the human eye can detect, enabling dramatic improvements in backlighting of LCD displays while simultaneously allowing dramatic contrast ratios and high resolution. One of the biggest challenges for automotive lighting systems designers is how to optimize all the benefits of the latest generation of LEDs. As LEDs generally require an accurate and efficient DC current source and a means for dimming, the LED driver IC must be designed to address these requirements under a wide variety of conditions. Power solutions must be highly efficient, robust in features and be very compact as well as cost effective. Arguably, one of the most demanding applications for driving LEDs will be found in avionic, marine and automotive infotainment TFT-LCD backlighting applications as they are subjected to the rigors of the automotive electrical environment, must compensate for a wide variation of ambient lighting conditions and must fit in a very space-constrained footprint, all while maintaining an attractive cost structure.

Benefits such as small size, extremely long life, low power consumption and enhanced dimming capability have triggered the wide spread adoption of LED TFT-LCD backlighting in today's automobiles, planes and boats. Infotainment systems usually have an LCD screen mounted somewhere in the center of the dashboard so both the driver and the passenger can easily view their location, perform audio tuning and a variety of other tasks. Additionally, many cars also have LCD displays that entertain passengers in the rear seat with movies, video games and so forth. Historically, these displays used CCFL backlighting, but it is becoming more common to replace these relatively large bulbs by very low-profile arrays of white LEDs which provide more precise and adjustable backlighting as well as a service life that will easily out live the vehicle . The benefits of using LEDs in this environment have several positive implications. First, they never need to be replaced, since their solid state longevity of up to 100K+ hours (11.5 service years) surpasses the life of the vehicle. This allows automobile manufactures to permanently embed them into "in cabin" back lighting without requiring accessibility for replacement. Styling can also be dramatically changed as LED lighting systems do not require the depth or area required by CCFL bulbs. LEDs are also generally more efficient than fluorescent bulbs at delivering light output (in lumens) from the input electrical power. This has two positive effects. First, it drains less electrical power from the automotive bus, and equally important, it reduces the amount of heat that needs to be dissipated in the display, eliminating any requirement for bulky and expensive heat sinking. Another important benefit of LED backlighting is the wide dimming ratio capability provided by a high performance LED driver IC. As the interior of a car is subjected to a very wide variation of ambient lighting conditions, ranging from direct sunlight to complete darkness with every variation in between, it is imperative that the LED backlighting system is capable of very wide dimming ratios, generally up to 30,000:1. With the proper LED driver IC, these wide dimming ratios are relatively easy to attain which are not possible with CCFL backlighting. Figure 1 shows a typical LCD-based virtual dashboard.

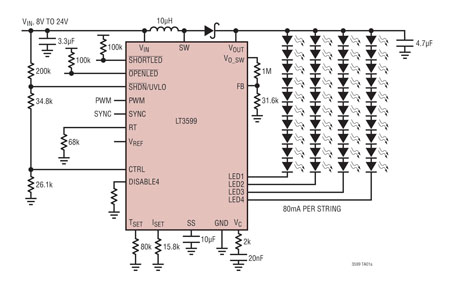

In order to ensure optimal performance and long operating life, LEDs require an effective drive circuit. These driver ICs must be capable of operating from the caustic automotive power bus and also be both cost and space effective. In order to maintain their long operating life, it is imperative that the LEDs current and temperature limits are not exceeded. One of the automotive industry's major challenges is overcoming the electrically caustic environment found on the car's power bus. The major challenges are transient conditions known as load dump and cold crank. Load-dump is a condition where the battery cables are disconnected while the alternator is still charging the battery. This can occur when a battery cable is loose while the car is operating, or when a battery cable breaks while the car is running. Such an abrupt disconnection of the battery cable can produce transient voltage spikes up to 40V as the alternator is attempting a full-charge of an absent battery. Transorbs on the alternator usually clamp the bus voltage to approximately 36V and absorb the majority of the current surge. However, DC/DC converters down stream of the alternator are subjected to these 36V to 40V transient voltage spikes. These converters are expected to survive and regulate an output voltage during this transient event. There are various alternative protection circuits, usually transorbs, which can be implemented externally. However, they add cost, weight and take up space. "Cold crank" is a condition that occurs when a car's engine is subjected to cold or freezing temperatures for a period of time. The engine oil becomes extremely viscous and requires the starter motor to deliver more torque, which in turn, draws more current from the battery. This large current load can pull the battery/primary bus voltage below 4.0V upon ignition, after which it typically returns to a nominal 12V. However, there is a new solution to the dilemmas, Linear Technology's LT3599, which is capable of both surviving and regulating a fixed output voltage through out both of these conditions. Its input voltage range of 3V to 30V with transient protection to 40V makes it ideal for the automotive environment. Even when VIN is greater than VOUT, which could occur during a 36V transient, the LT3599 will regulate the required output voltage. As most LCD backlighting applications require between 10 and 15watts of LED power. Linear Technology's LT3599 has been designed to service this application. It can boost the automotive bus voltage (nominal 12V) to as high as 44V to drive up to four parallel strings, each containing ten 100mA LEDs in series. Figure 2 shows a schematic of the LT3599 driving four parallel strings, each string comprised of ten 80mA LEDs, delivering a total of 12W.

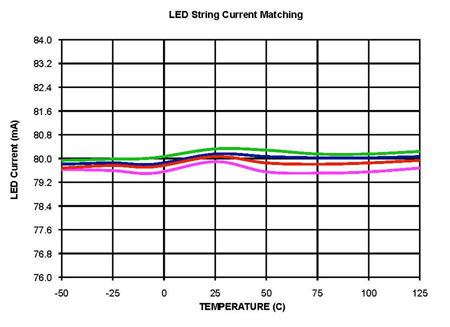

The LT3599 utilizes an adaptive feedback loop design which adjusts the output voltage slightly higher than the highest voltage LED string. This minimizes power lost through the ballasting circuitry to optimize the efficiency. Figure 3 illustrates the LT3599's efficiency that can be as high as high as 90%. This is important because it eliminates any requirement for heat sinking, enabling a very compact low profile footprint. Equally important for driving arrays of LEDs is to provide accurate current matching to insure that the backlighting brightness remains uniform across the entirety of the panel. The LT3599 is guaranteed to deliver less than 2% LED current variation across its -40?C to 125?C temperature range.

The LT3599 uses a fixed frequency, constant current boost converter topology. Its internal 44V, 2A switch is capable of driving four strings of up to ten 100mA LEDs connected in series. Its switching frequency is programmable and synchronizable between 200kHz and 2.5MHz, enabling it to keep switching frequency out of the AM radio band while minimizing the size of the external components. Its design also enables it to run one to four strings of LEDs, if fewer strings are used; each string is capable of delivering additional LED current. Each string of LEDs can use the same number of LEDs or can be run asymmetrically with a different number of LEDs per string. The LT3599's offers direct PWM with dimming ratios as high as 3,000:1 and dimming analog dimming via the control pin, which offers ratios as high as 20:1. In applications which require dimming ratios of up to 30,000:1, these two dimming functions can be combined to reach the required ratio. Certain emerging automotive, marine and avionic applications often require these very high dimming ratios to compensate for a wide range of ambient light that the LCD panel is subjected to. Furthermore, the LT3599 has integrated protection features that include open and short circuit protection and alert pins. For example if one or more LED strings are open circuit, the LT3599 will regulate the remaining strings. If all of the strings are left open, it will still regulate the output voltage and in both cases would signal the OPENLED pin. Similarly, if a short circuit occurs between VOUT and any LED pin, the LT3599 immediately turns off that channel and sets a SHORTLED flag. Disabling the channel protects the LT3599 from high power thermal dissipation and ensures reliable operation. Other features that optimize reliability include output disconnect in shutdown, programmable under voltage lockout and programmable LED temperature derating. The high voltage capability and high level of integration of the LT3599 offers an ideal LED driver solution for automotive back-lighting applications. The unprecedented acceleration of LED backlighting applications in automotive displays is driven by a continual demand for higher performance and cost effectiveness. These emerging performance requirements must be enabled by new LED driver ICs. These LED drivers must provide constant current in order to maintain uniform brightness, regardless of input voltage or LED forward voltage variations, operate with high efficiency, offer wide dimming ratios and have a variety of protection features to enhance system reliability. These LED driver circuits also require very compact, low-profile, thermally efficient solution footprints. Linear Technology is continually improving their family of LED drivers to meet these challenges head on with LED driver ICs like the LT3599 for display applications. In Addition, Linear Technology has developed an entire family of high current LED driver ICs aimed at myriad of automotive applications ranging from LCD backlighting to turn signals and even headlight applications. As automotive lighting systems continue to demand higher performance LED drivers, Linear Technology will meet these challenges. www.linear.com