Author:

Frederik Dostal, Analog Devices

Date

10/11/2013

Different health care applications require different power management solutions. From a power management view, health care is a very interesting market. Though design cycles within health care are quite long, a high level of innovation is fueling the need for new health care electronics. These do not only replace older apparatus but are used in new markets and applications which did not exist a few years ago. This article will look into four different health care application areas. They are home health care, instrumentation, patient monitoring and imaging. Power management solutions are discussed for each individually. Home Health Care Within home health care we see vast design activity. The global pressures of aging societies, growing economic strength, and technical innovation have led to many new applications for home health care. The benefits for patients include increased flexibility, better services, and possibly fewer trips to the doctor. While home health care has been around for quite some time, only recently do we see more and more advanced solutions available to consumers. Examples of such solutions are monitors for activity, blood pressure, and heart rate. In addition, portable blood analyzers and pulse oximetry systems are included in today's home health care. From a power management perspective all these systems require a high level of integration due to the necessary portability. High power efficiency is needed for systems which are truly portable and thus battery operated. Here lower power consumption will increase the operation time of the device without recharging or replacing batteries. Lastly, one important specification is also the cost. While in some other health care applications the cost of a power management solution might not be a key specification, in home health care it is. Here cost constrains come close to what we see in the consumer electronics market. Figure 1 shows a power chain for a rechargeable system utilizing a lithium-ion battery. The power architecture ensures that some parts of the circuit can be turned off using a load switch such as the ADP190, while other circuitry, such as the ADP160 powering the real time clock (RTC) is always turned on. The ADP190 has a ground current lower then 2?A when turned on and the ADP160 only consumes about 560nA of supply current with no load. This keeps the permanent discharge of the battery at a minimum. The ADP2140 is a highly integrated buck switching regulator combined with a linear regulator. This power management unit is saving space and cost. To charge the lithium-ion battery, advanced battery charging solutions such as the ADP5065 are available. This device is a very efficient switching mode charger which is especially suitable to medical applications due to its many error detection and safety functions. It is fully compliant with the USB 2.0, USB 3.0, and USB battery charging specification 1.1 and enables charging via mini USB VBUS pin from a wall charger, car charger, or USB host port.

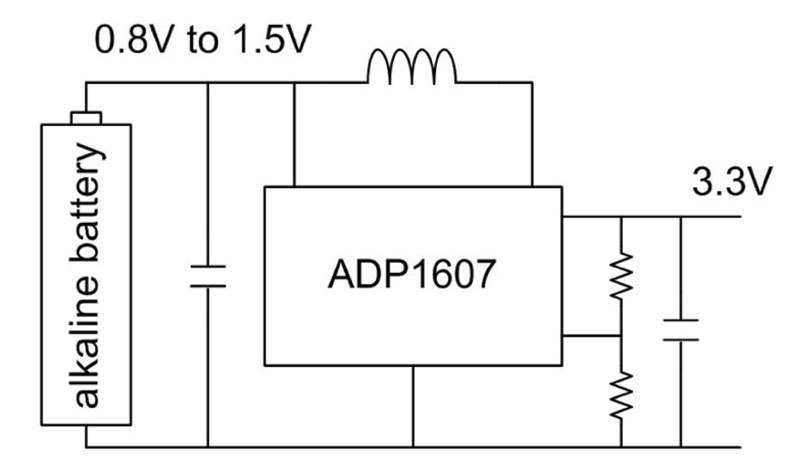

Some lower cost portable heath care systems, which are only used for short amounts of time, might be designed around a non-rechargeable alkaline battery. For weight and cost reasons there is a benefit when using only one battery cell than the common two cell setup. The difficulty of one alkaline cell systems is that the battery voltage is only in the range from 0.8V to 1.5V. To power the electronics, a boosting regulator capable of such low input voltages with high power efficiency is necessary. Figure 2 shows the ADP1607 as a first power conversion step for such an application. It is generating 3.3V which is needed in most systems. Instrumentation Example applications in instrumentation are blood analysis, dialysis machines as well as clinical diagnostics. Instrumentation equipment is usually not portable. The power management requirements are not so much driven by the factors discussed in the ‘home health care' section. In instrumentation we have usually more power available, thus power efficiency is not such a big concern. While a high level of integration is definitely a ‘nice to have', it is often times not essential. What matters for instrumentation applications is very often low noise. Switching regulators as well as linear regulators need to be very low noise in order to allow for very high precision measurements. Typically a silver box type AC / DC power supply is used to generate one or multiple intermediate voltages. These rails are then used to generate lower voltages.

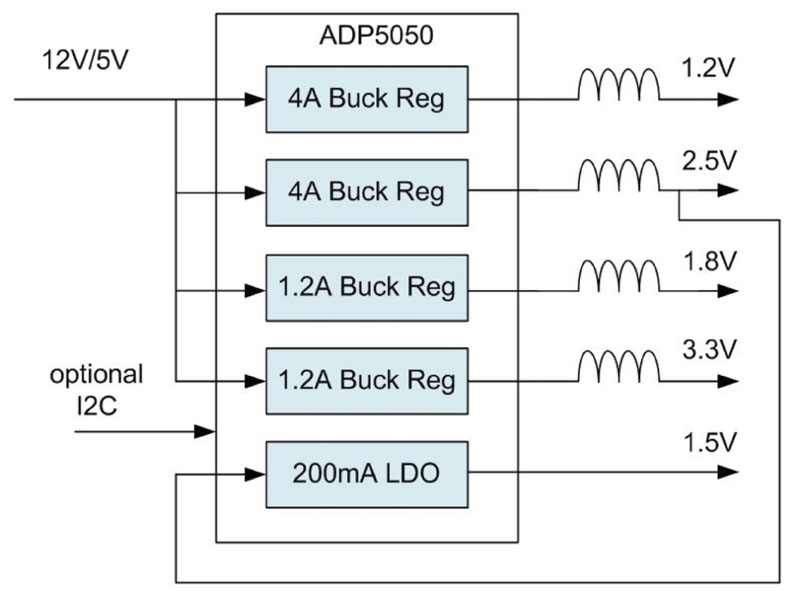

Figure 3 shows a micro PMU (Power Management Unit). It is an ADP5050 which can operate of a 12V rail coming from the AC / DC power supply. This PMU includes four switching regulators as well as one linear regulator. While being compact, it also includes many desirable functions. Switching frequencies of the individual step down regulators are synchronized together and phase shifted for minimum noise on the input line and to enable small input capacitors. One unique feature is to be able to run two of the switching regulators at half the switching frequency of the other two regulators. This maintains a predictable low EMI profile while being able to use a higher switching frequency for a low power rail while using a lower switching frequency on a high power rail for highest efficiency. Last but not least, there is an I2C interface available to dynamically change the output voltage, check chip temperature, set the phase shift of different channels, power good indication and enable of individual channels. These functions help intelligent instrumentation systems to monitor and control the power management.

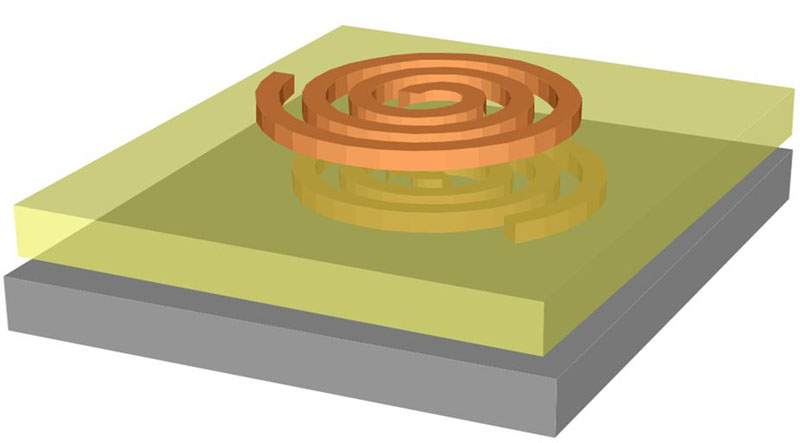

Patient Monitoring Systems in this category are clinical based. They are used to measure blood pressure but also in electrocardiography (ECG) and pulse oximetry systems. Here power management is usually line powered, thus power efficiency is not so important as long as dissipated heat can be managed. What really matters is reliability, galvanic isolation for safety purposes as well as low noise. For reliability, battery backup is sometimes provided. It is helpful when patients are transferred to different hospital stations and vital signs monitoring shall not be interrupted. Isolation needs to comply to the most stringent medical safety standard IEC 60601-1. Digital isolation with Icouplers® is replacing optocouplers without compromising isolation integrity. The advantage is to avoid the aging effects of optocouplers for long term reliability as well as the availability of different semiconductor functions such as USB, I2C and power management switching regulators all in one package. These devices are capable of reinforced insulation and can withstand a 10kV surge as designated by IEC 60747-5-5. Icoupler products are using chip scale transformers which provide very robust common-mode transient immunity compared to optocouplers and capacitor based digital isolators. Figure 4 shows the concept of inductive isolation. There are two inductors with an insulation barrier in between which consists of Polyimide, SiO2 or similar isolation materials.

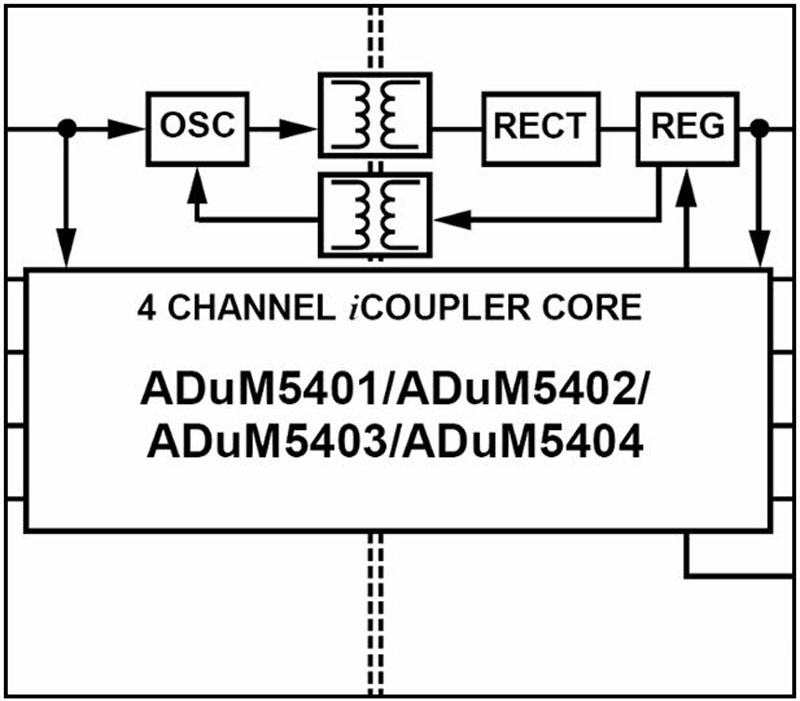

Figure 5 shows a block diagram of a typical Icoupler device with Isopower functionality. Isopower is able to not only couple signals through an isolation barrier, but also power. The ADuM540x can deliver a total power of up to 500mW. Besides the coupling of power, the chip also integrates up to 4 channels of data coupling.

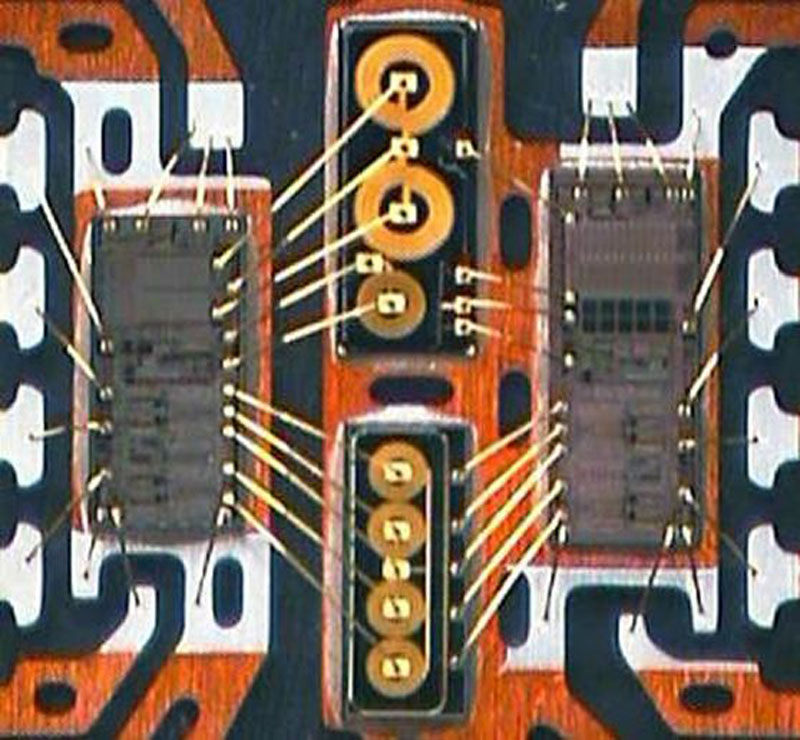

Figure 6 shows a photograph of the system inside the microchip package. Imaging These applications have come a long way. It truly is fascinating which advancements have been made in the field of imaging. This product group includes ultrasound, CT (computer tomography), digital X-ray, MRI (magnetic resonance imaging) and PET (positron emission tomography). Power management wise we see two trends. Larger systems such as MRI and PET are quite power hungry and require many distributed power supplies. These need to have a certain level of efficiency for heat dissipation purposes. In imaging applications it is very likely that any type of system noise, including switching noise or even LDO output voltage noise, may be visible on the final image. It can mean ordinary error lines in the image but sometimes we also see picture quality degradation in contrast and color or grey scale levels. Power supplies can introduce problems on the image sensing circuitry but also on the image display circuitry. Resulting picture quality issues in both parts of an imaging system are not acceptable. There are manufacturers of medical imaging equipment who used power management modules before but decided against them. While they would come with a guaranteed principle specification, the exact EMI behavior was not guaranteed. The slightest change in the manufacturing of the power modules could potentially yield issues in picture quality. In order to have a higher level of control, a discrete power design, fully developed and manufactured by the health care imaging design company can be the better way to go. Conclusion Power management requirements in health care applications are quite different depending on the application area. In all areas we see the requirement for specialized solutions. In home health care many solutions will be ASSP (application specific standard product) or even ASIC (application specific integrated circuit) based. The smaller quantity applications will use standard of the shelf power management units. In instrumentation, patient monitoring and imaging, power management solutions will be even more optimized to play well with the ultra-high accuracy signal path components. Analog Devices