Author:

Reported by Cliff Keys, Editorial Director, Editor-in-Chief, Power Systems Design

Date

11/25/2010

SUYIN's booth was busy and demonstrated the strength and breadth of solutions the company has established for itself in Europe. The company's high quality standard off-the-shelf and tailored custom products can fit every need for the designer with SUYIN's customer support and service always on hand.

The more mobile our society becomes, the stronger the demand for battery-powered devices. SUYIN offers the right battery connector for nearly any kind of application, from mobile phones and notebooks to portable devices for industrial, automotive, and medical device applications. And if the tremendous range of ready-to-order battery connector solutions (with well over 1,000 different variants) does not include the solution that you are looking for, SUYIN's special strength comes into play: Fast development and production in accordance with customer specifications.

Insert: 17_Bild_02_kundenspez_Batteriesteckverbinder_Beispiele SUYIN's line of stock battery connectors can, with a few exceptions, be divided up into two basic contact categories: spring contacts (max. typical current carrying capacity of up to 5 A) and blade contacts (max. typical current carrying capacity of up to 7 A). Battery connectors with spring contacts are particularly cost efficient, and they ensure user-friendly handling, because they establish direct contact with the battery's contact surfaces. Due to their small dimensions, they are ideally suited for compact applications with tight space constraints. The plug-and-socket systems with blade contacts feature excellent robustness and mating reliability (sliding contacts). As a result, they are also well suited for industrial applications that operate under extreme environmental conditions. Selection of stock connectors made easy: Whether spring contacts, blade contacts or other types of contacts are needed, when it comes to finding the right contact within its huge range of offerings, SUYIN does not leave its customers alone with (web) catalogs. On the basis of the application details, SUYIN's onsite support staff determine the ideal solution in a particularly fast manner and in a way that is simple and convenient for the customer. Customer-specific battery connectors make it possible to customize the design to match the end device. The ideal miniaturization that this allows offers the greatest possible space savings for the application. Furthermore, adhering to the "design-to-cost" principle ensures consistent realization of the least expensive solution - all the way to suitable packaging for automatic assembly. Example of custom battery connectors: Two different battery connector versions for two distinct series of devices Several of the advantages are illustrated by the 250097GA series of battery connectors, which was developed to customer specifications. This battery connector, which is equipped with spring contacts for surface mounting, is available in two versions for two different series of devices. They each have different connector heights and different numbers of contacts as well as a different exterior design for the connector housing. Moreover, in accordance with customer specifications, a first-make/last-break spring contact, an additional SMT soldering contact and the possibility for employing screw fastening for ideal handling of extraction forces were integrated. The contact forces were also defined to meet customer-specific requirements. Two positioning posts with different diameters safeguard against improper alignment. Last but not least, the use of identical ground (earth) contacts in the spring area and in the soldering area for two different versions offers considerable potential for reducing the design and tool costs. SUYIN connects European Requirements with East Asian Design and Manufacturing Expertise There are many East Asian manufacturers - with headquarters in China, Japan or Taiwan, for example - that make high-quality, reliable electromechanical and optoelectronic components. But what differentiates these companies from one another, and what makes a specific vendor attractive for customers/users - particularly here in Europe?

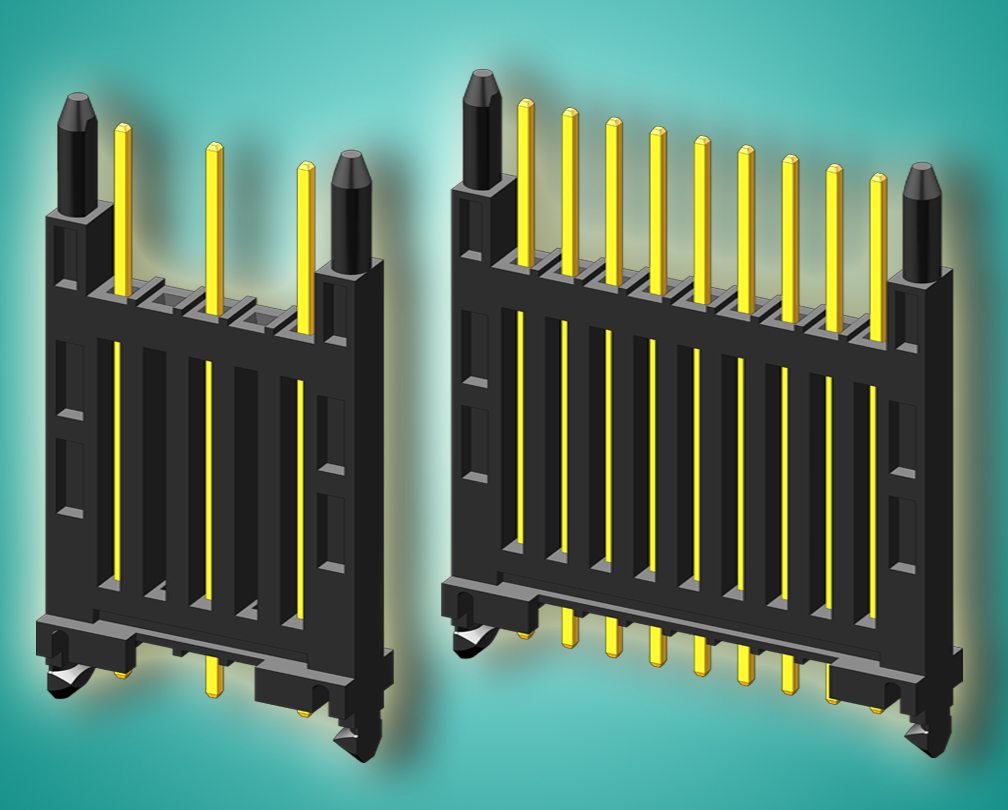

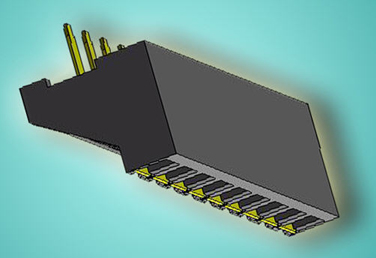

SUYIN ECO (SUYIN's European Central Organization) responds to this question with a service and communications structure that is tailored to match European requirements and expectations. The organization's "We speak European" motto refers to more than just the different languages. It also refers to the ability to understand the different national mentalities and cultural backgrounds. After all, It's very important to gain a solid understanding of the wishes and expectations of European customers right from the beginning in order to then be able to implement them precisely in the correct language and style at the company's design, production and testing facilities in the Far East - in close cooperation, of course, with the specialists there. Communication and coordination in the other direction, from Asia to Europe, also requires a great deal of effort and experience. In short: SUYIN ECO connects its customers' requirements to the company's own technical capabilities in working processes. A key factor that differentiates SUYIN from other East Asian vendors is the fact that customers do not have to adapt to pre-defined standard solutions. Instead, SUYIN orients itself with great flexibility on its customers' desires and develops and manufactures its products in accordance with individual customer specifications. Customers describe their applications and the solutions that they would like to have, including all of the requirements with regard to the design, quality, quantities, and other aspects, such as logistics. SUYIN ECO's customer care representatives then take on responsibility for project management, which ranges from constant "bilateral" communication to the definition of requirements and the initial product design drafts and continues all the way to quality management (discrepancy and 8D reporting). When it comes to order processing, too, SUYIN demonstrates a high level of flexibility and offers its customers tailored logistics solutions (such as a framework agreement, buffer warehouse, consignment warehouse, etc.). Departments specializing in different industries - such as the Automotive and Industrial Connector Business Unit (AICBU) and Networking Connector Business Unit (NCBU) - ensure fast, reliable interconnect solutions that comply with all relevant industry standards. Due to SUYIN's automated robotic production lines, the manufacturing processes, which are supported by the in-house quality testing lab (National Class 2 Lab), can manage high volumes with particular flexibility. "We speak European" means: SUYIN understands European market requirements and links them with East Asian design and manufacturing expertise. Fast, Capable and Affordable Customer-Specific Problem Solvers SUYIN offers many different types of board-to-board (BTB) connectors. This broad selection begins with versions featuring contact configurations that range from very simple to highly complex and cover a wide variety of pitches - from 0.5mm (fine pitch) all the way to 2.54mm. The fact that the overwhelming majority of these products are custom solutions comes as no surprise, because SUYIN is one of the very few East Asian connector vendors that are able to realize custom developments or modifications (for example, with regard to the pin length, gold plating, housing or packaging) at absolutely competitive prices. Additional characteristics that set SUYIN apart include fast, comprehensive, and highly capable customer support on location coupled with knowledge gained through many years of experience in meeting the special technical challenges and stringent quality requirements that European customers face. These advantages are then combined with the capabilities offered by ultramodern and extremely flexible design, manufacturing and testing facilities in East Asia, and then rounded off with punctual delivery and highly attractive pricing.

A case in point: "Sandwich" pin headers with bottom-entry sockets Some of the key requirements facing a European customer for a "tailored" BTB solution in industrial applications have included: