Author:

Bruce Haug, Sr. Product Marketing Engineer, Power Products, Linear Technology

Date

09/27/2011

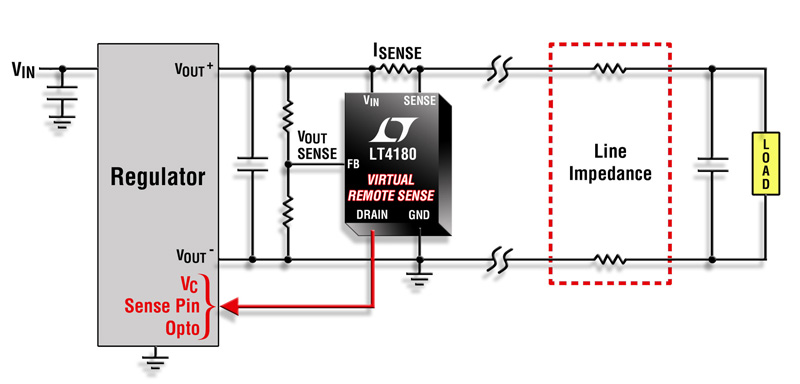

Even before the heightened awareness brought on by threats of terrorism, many public and private institutions had already began to incorporate video security into critical infrastructure. Video security provides the visual images necessary to improve situation awareness, deter vandalism, theft or other crime, accelerate response and management decisions and increase overall staff and public safety. From airports to bridges, refineries to pipelines, seaports to highways, all have benefited from including video security equipment in their preparedness plans. One of the most demanding video security installations is a casino, where the sleight of hand and the quickest of movements must be captured, reviewed and archived to meet stringent regulations. The strategic placement of "eye in the sky" cameras supplements a security staff's physical resources, helping to better manage crowds and deploy personnel in a timely and effective manner. High-quality video of gaming areas provides security professionals with the detailed information needed to prevent cheating and to catch cheaters. Surveillance cameras can also help deter crime while aiding authorities in identifying criminals during their investigations. Retail stores benefit from video surveillance systems by serving as a visual deterrent to potential criminal acts and provide managers and security professionals with tools for dealing with liability claims, employee theft or other management issues. As a result, shoplifting and employee theft can be dealt with more easily when the perpetrator is caught in the act on video. Furthermore, slips, falls and liability claims can be more accurately understood and processed when caught on video. Contraband, violence, inmate and officer safety are just a few of the issues that must be dealt with on a routine basis in the management of today's correctional facilities. And so, video security has never played a more important role in maintaining order and ensuring a safe working environment. These systems provide 24/7 monitoring of remote locations. As a result, some of the monitoring cameras need to be several hundreds of feet away from the base control system or available power outlet. As healthcare facilities grow larger and provide around-the-clock care, they become more vulnerable to a wide array of security risks. While industry guidelines mandate a growing reliance on security under its "Environment of Care" standards, it is the responsibility of each individual hospital and healthcare organization to decide on the right tools to meet their needs for protecting patients, visitors, staff and intellectual property. Camera Deployment To get complete surveillance coverage at certain sites, somewhere between 200 to 300 cameras may needed. These cameras could potentially be from up to 1000 feet from the base control system or an AC outlet. Each camera requires its own power for operation and typically needs 24V DC at about 20W unless it is mounted in an open environment, where it is subjected to the elements and needs to be heated to prevent ice from forming. In this case, the power demand can approach 70W. Therefore, the system integrator needs to either have an electrician install an AC outlet box close to the camera or power the camera through a long run of wires. Long wire runs can produce a large voltage drop causing considerable load regulation errors. As the load current increases, the voltage drop in the wiring increases due to the line impedance and the voltage delivered to the load drops. System integrators have routinely increased the wire size from 22 AWG to 16 AWG to maintain regulation even though the cost delta between these wires sizes can be as high as $250 for a 1000 foot wire run. Alternatively, the traditional approach to solving this problem has been to sense the output voltage with a pair of sense wires that run from the regulator's feedback network to the load. While this approach works well, the additional pair of low gauge wires, typically 26 AWG may not be practical due to the cost, weight or logistic considerations. Figure 1 shows a remote sense block diagram with one wire sensing the voltage drop in the positive voltage wire and the other wire sensing the drop in the negative voltage wire.

A New Solution Linear Technology has developed the LT®4180 Virtual Remote Sense™ (VRS) controller, eliminating the need for remote sense wires to compensate for the IR losses in cables and wiring. This device continuously interrogates the line impedance and corrects the power supply output voltage to maintain a steady voltage at the load regardless of current changes. The block diagram in Figure 2 shows the LT4180 VRS controller's basic operation. How VRS Works VRS works with a small modulation on the output of the regulator to compute the correction. This modulation is filtered by an output capacitor at the load that is always present anyway. The LT4180 works with nearly any conversion topology, isolated or non-isolated power supplies, DC/DC converters including bricks, modules and adjustable linear regulators. The LT4180 operates in conjunction with a power supply or DC/DC converter and forces the output current to change from 95% and 105% of the nominal output current at a pre-determined dither frequency. In other words, the LT4180 forces a square wave current with a peak-to-peak amplitude equal to 10% of the DC current on top of the regulators output current (IL). A decoupling capacitor at the load filters out the dither current from the VRS square wave. This decoupling capacitor is sized to produce an "AC short" at the current square wave frequency, resulting in a voltage square wave at the power supply with peak-to-peak amplitude equal to 1/10 of the line impedance. The LT4180 continuously monitors the line impedance and corrects the regulators output voltage to provide accurate load regulation.

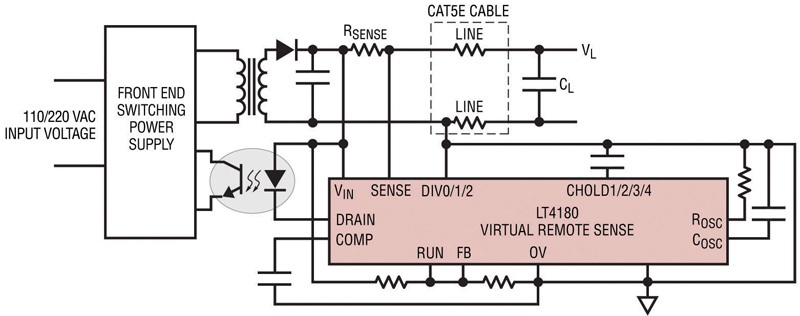

Off-Line Design Example The simplified circuit in Figure 3 shows how the LT4180 can be designed into an off-line power supply to deliver 24V @ 0.7A with a 3A peak output through a CAT5E cable to power a video surveillance camera. The LT4180 continuously monitors the line impedance of the CAT5E cable and its DRAIN pin drives the diode in an optocoupler to change the duty cycle of the power supply in order to maintain tight regulation at the load regardless of load current changes.

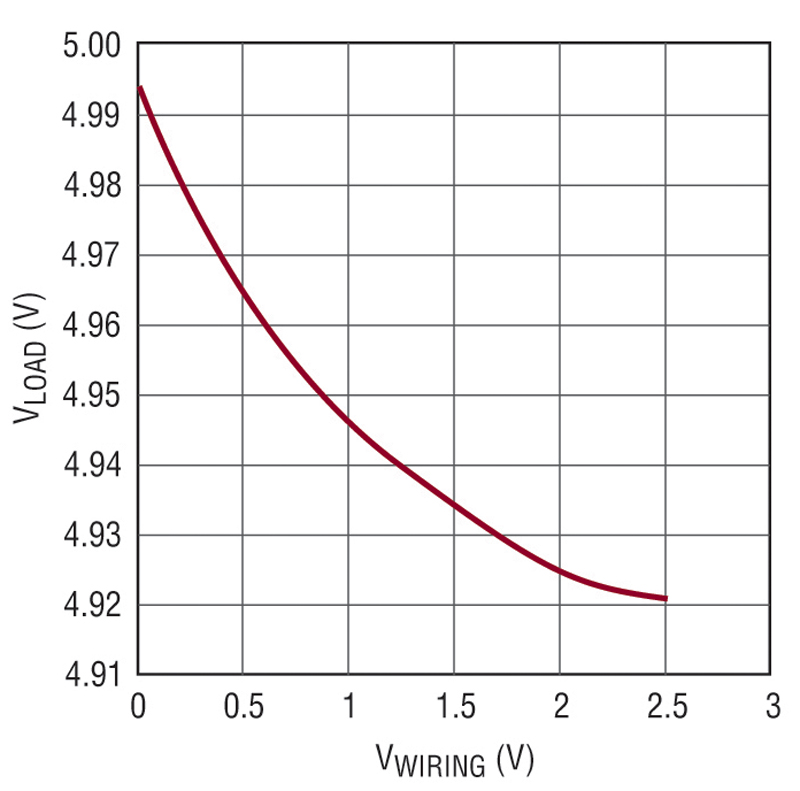

The curve in Figure 4 shows the load regulation of a LT4180 line loss compensation circuit for a 5V output voltage. The load current is increased from zero until it produces a 2.5V drop in a cable. With the LT4180 correcting the power supplies duty cycle results in only a 73mV change in voltage at the load over the entire load range. Additional Benefits The LT4180's 3V to 50V input voltage range covers a variety of applications. Its output driver has a 5mA sink capability to drive an opto-coupler for isolated designs. A programmable fixed dither frequency or spread spectrum frequency determines the sampling rate of the line impedance. The soft-correct function insures an orderly start-up. When the run pin rising threshold is first exceeded (indicating VIN has crossed its undervoltage lockout threshold), the power supply output voltage is set to a value corresponding to zero wiring voltage drop (no correction for wiring). Over a period of time (determined by the CHOLD4 pin on the LT4180), the power supply output ramps up to account for the wiring voltage drop, providing best load-end voltage regulation. A new soft-correct cycle is also initiated whenever an overvoltage condition occurs. The LT4180 is available in an SSOP-24 package with three temperature grades. An extended grade version from -40 to 85°C, an industrial grade version from -40°C to 125°C and a military grade from -55°C to 125°C. Conclusion The LT4180's VRS provides a new function for power supply designers and system integrators. Excellent regulation is obtained without sense wires for long wire runs to cameras and eliminates the need for additional power outlets or much heavier gauge wires. VRS opens up opportunities previously unavailable in surveillance equipment installation and works with nearly any type of power supply or regulator: switching or linear, isolated or non-isolated, providing maximum flexibility. www.linear.com