Blake Stringer, Ph.D. (right), assistant professor of aerospace engineering in Kent State University's College of Aeronautics and Engineering, and research assistant Kendy Edmonds study the power needs for a new larger generation of drones, seen above, for a research grant funded by the Army Research Laboratory.

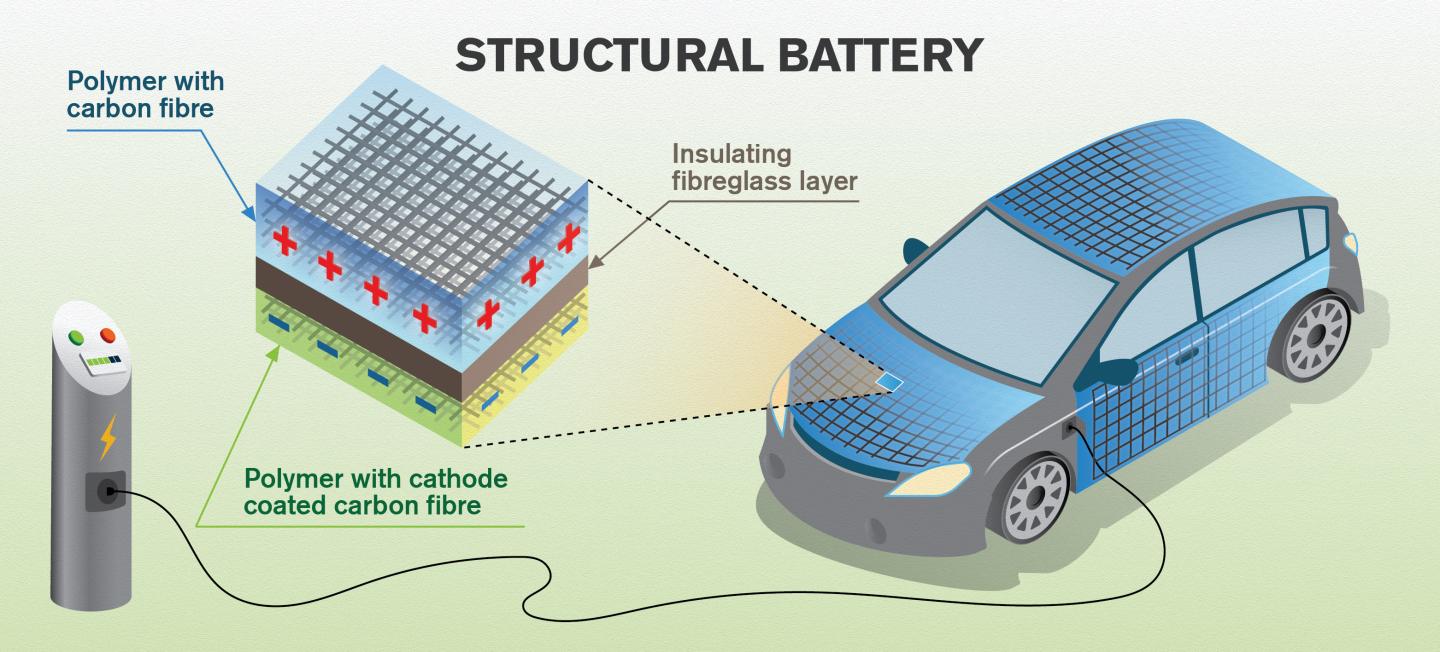

The researchers' vision is of vehicles where a large part of the car-body or aeroplane-fuselage consists of structural lithium ion batteries. Multi-functional carbon fibre can work as battery electrodes and load-bearing material consecutively. The researchers work with structural lithium ion batteries where the negative electrodes are made of carbon fiber and the positive electrodes are made of cathode-coated carbon fiber. In the picture, the battery is charged, which means the negative electrode is filled with positively charged lithium ions.

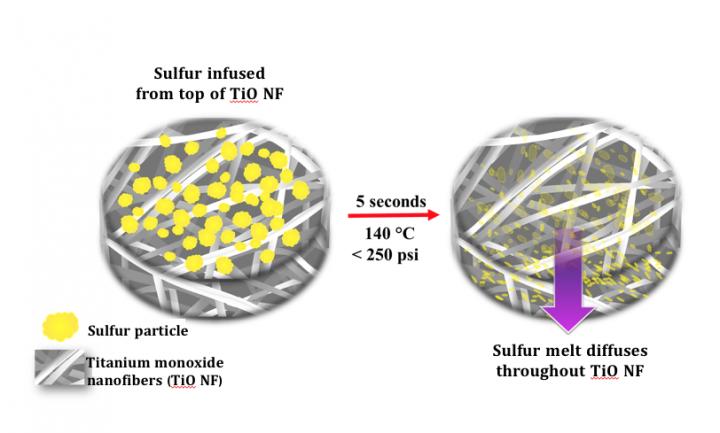

The hot-press procedure, developed at Drexel, melts sulfur into the nanofiber mats in a slightly pressurized, 140-degree Celsius environment -- eliminating the need for time-consuming processing that uses a mix of toxic chemicals, while improving the cathode's ability to hold a charge after long periods of use.