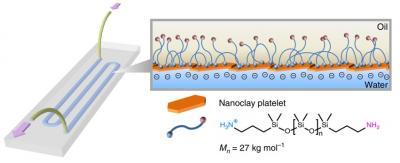

To make the 3D-printable fluidic device, Berkeley Lab researchers designed a specially patterned glass substrate. When two liquids - one containing nanoscale clay particles, another containing polymer particles - are printed onto the substrate, they come together at the interface of the two liquids and within milliseconds form a very thin channel or tube about 1 millimeter in diameter.

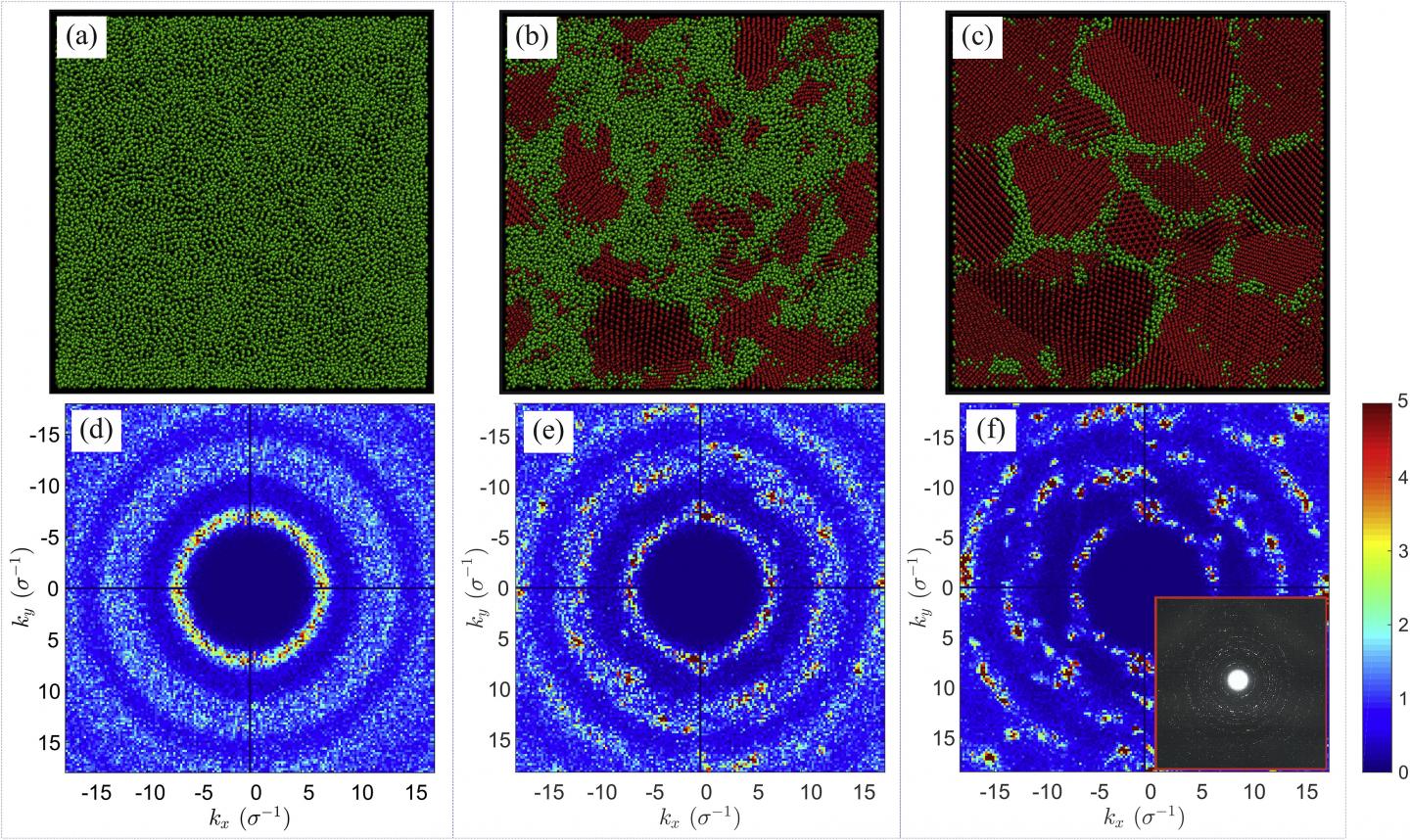

Top panels: snapshots of the system at the temperature and at different times from start of crystallization: (a) glassy system without the crystallization centers; (b) two-phase state of the system containing crystalline nuclei; (c) polycrystalline system consisting of separate crystalline domains. Bottom panels: -projections of the glassy system (d), the two-phase system (e) and the polycrystalline system (f). Inset to panel (f) shows the diffraction pattern obtained by transmission electron microscopy for polycrystalline foil.