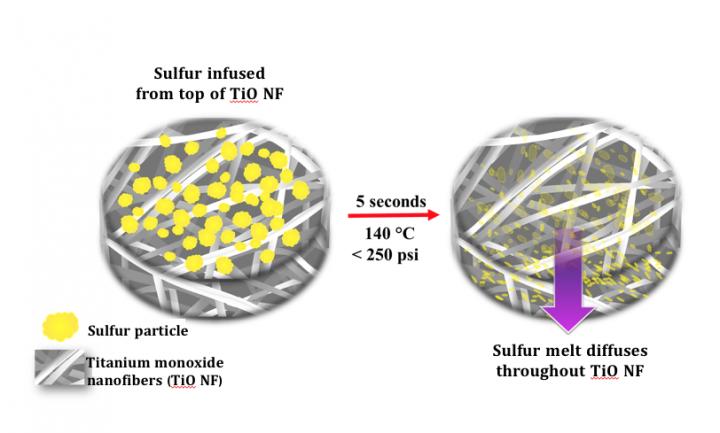

The hot-press procedure, developed at Drexel, melts sulfur into the nanofiber mats in a slightly pressurized, 140-degree Celsius environment -- eliminating the need for time-consuming processing that uses a mix of toxic chemicals, while improving the cathode's ability to hold a charge after long periods of use.