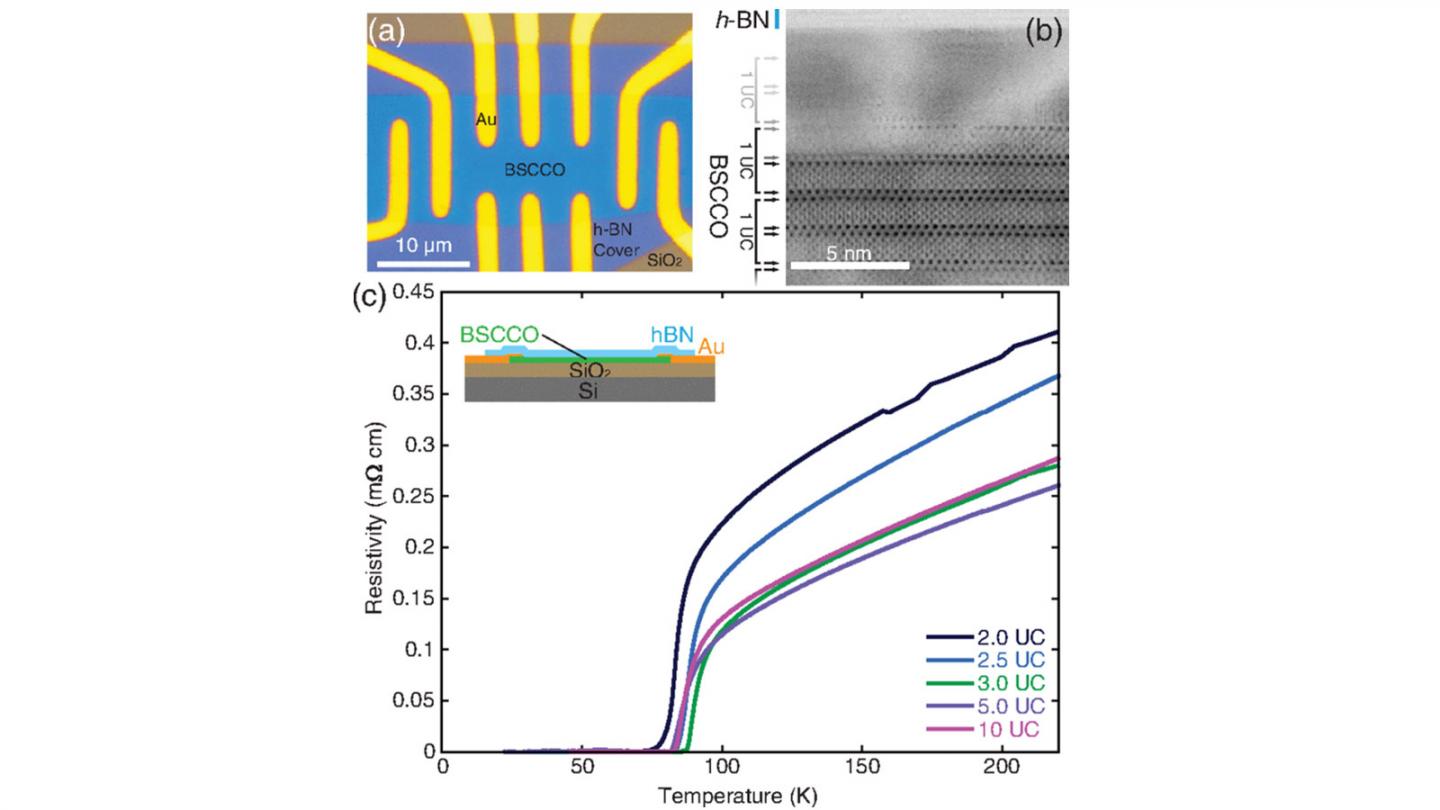

Graphic showing van der Waals BSCCO device. (a) Optical image of Hall bar device, (b) Cross-sectional view of a typical device in scanning TEM. Columns of atoms are visible as dark spots; black arrows point to bismuth oxide layers (darkest spots), while gray arrows show their extrapolated positions. (c) Resistivity as a function of temperature for devices of a different thickness.

Ujjwal Das, an associate scientist at the University of Delaware's Institute of Energy Conversion, examines a silicon wafer after a thin layer of sulfur - less than 5 nanometers thick - was deposited on the surface. In the background, doctoral students Robert Theisen and Isaac Lam watch a silicon wafer emerge from the atmospheric pressure vapor treatment reactor, where it was treated with hydrogen sulfide and hydrogen selenide gases. The reactor was developed at IEC.

Samarium sulfide doped with various rare earth elements shrinks as the temperature increases from about minus 175°C to about 40-60°C. Shown here is the relative linear shrinkage compared to the length at about 120°C. For the Cerium (Ce) dopant, the percentage volume decrease is about 2.6%. These samples were produced by an industrially scalable process, paving the way for practical applications of this class of sulfides as thermal-expansion compensators.

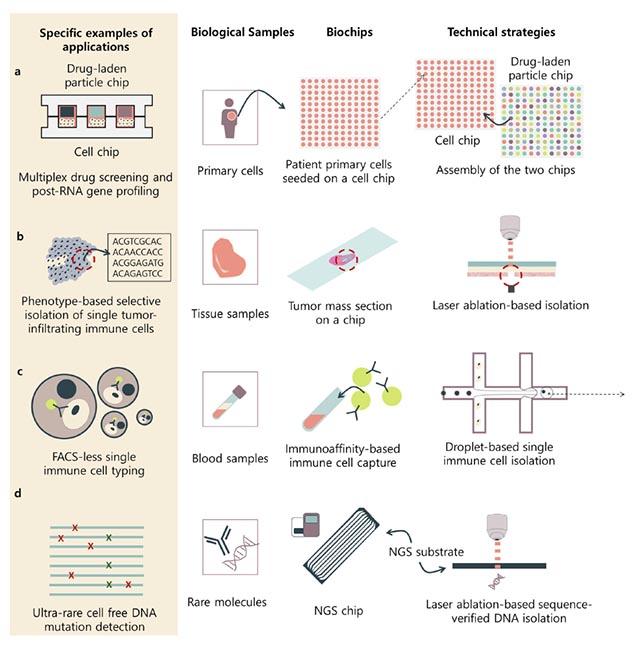

Biochips are driving next-generation DNA sequencing technologies, and this powerful combination is capable of solving unique and important biological problems, such as single-cell, rare-cell or rare-molecule analysis, which next-generation sequencing can't do on its own. In APL Bioengineering, researchers from Seoul National University explore the role advancements in biochip technology are playing in driving groundbreaking scientific discoveries and breakthroughs in medicine via next-generation sequencing, aka high-throughput sequencing. This image shows perspectives on potential biochips used for next generation sequencing for promising applications in biotechnology.

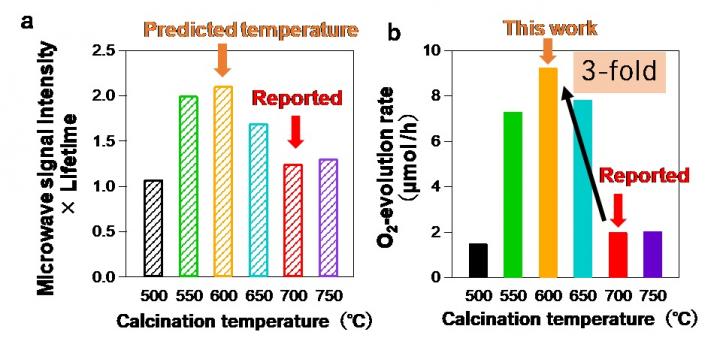

(a) Product of microwave photoconductivity intensity and its lifetime of oxyhalide photocatalyt 2 vs calcination temperature. The microwave measurements suggest the optimal temperature of 600 ? that is 100 ? lower than the reported one. (b) O2-evolution rate of oxyhalide photocatalyt 2 prepared by different calcination temperature.